Obtaining Vanillin from Technical Lignin Produced from Pulp

Huge amounts of technical or Kraft lignin are formed during pulp production. This lignin is difficult to process and so is usually just incinerated for heat production. A team of researchers have developed a green method for recovering the flavoring agent vanillin from this raw material.

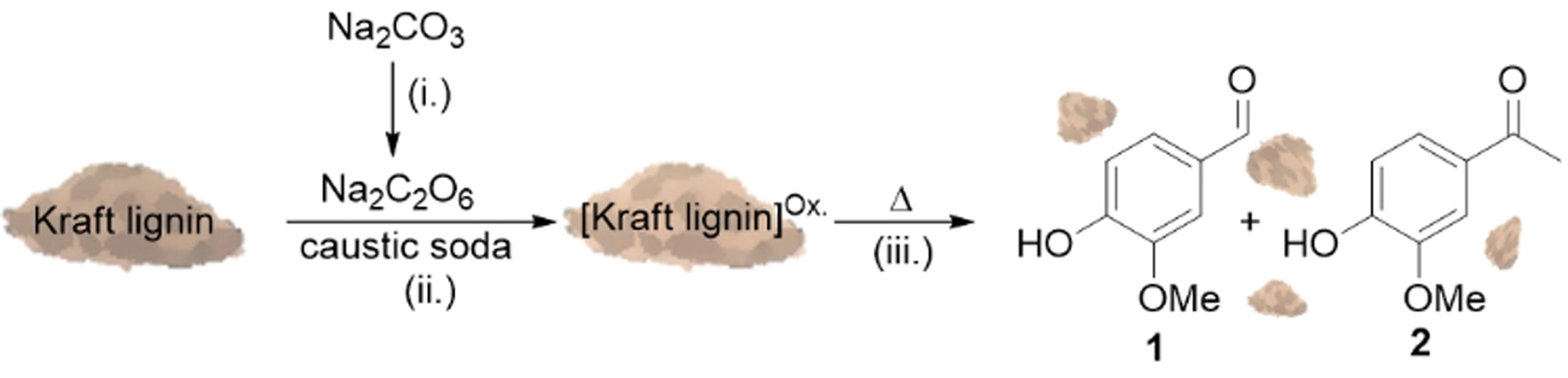

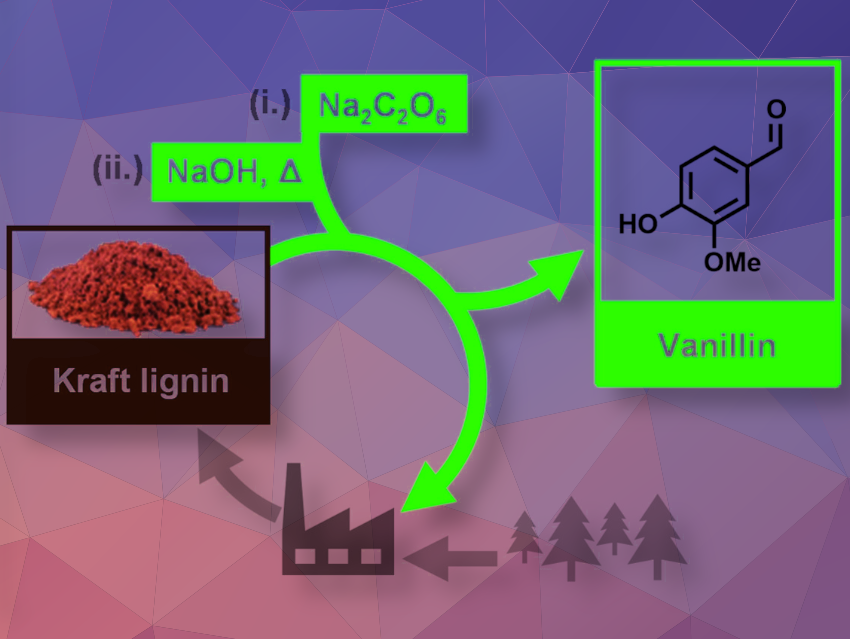

Using Na2C2O6 as “green” oxidizer, the team was able to oxidative depolymerize Kraft lignin into vanillin in yields up to 6.2 wt % and up to 92 % referring to the maximum yield obtained from the quantification reaction using nitrobenzene. Sodium peroxodicarbonate was synthesized through the electrolysis of aqueous sodium carbonate in yields up to 41 %. The materials used in this method are all recycled from papermaking processes, and only power and heat need to be added.

Kraft Lignin

Lignin and cellulose are essential components of wood. The molecular structure of lignin contains the structure of vanillin, the main flavoring substance from the vanilla plant, meaning that vanillin can be produced from lignin, although the process is laborious. At present, lignosulfonate, a substance also formed in some papermaking methods, is used for the industrial production of vanillin.

To make paper from wood fibers, all lignin has to be removed, otherwise the paper will take on the brown color of the lignin. However, the waste product in the most commonly used pulping method for industrial papermaking, the Kraft method, is not lignosulfonate but rather a technical lignin referred to as Kraft lignin. Kraft lignin is much harder to oxidize and depolymerize than other lignins and so at present cannot be used as a raw material. Instead, it is simply burnt as fuel for papermaking processes.

The Green Method

Siegfried Waldvogel and colleagues, University of Mainz, Germany, have discovered a method for producing vanillin from Kraft lignin. They say the method is environmentally friendly as it does not use any harmful chemicals, and it is convenient as it uses the raw materials present in pulp production. A key step in their method is the production of the oxidizer by electrolysis of sodium carbonate.

“The idea started many years ago when playing around with innovative electrode materials that make it possible to take simple carbonates and make an oxidizer from them,” explains Siegfried Waldvogel. One of these electrode materials was boron-doped diamond, and the researchers observed that, when carrying out electrolysis using this electrode material, the sodium carbonate was readily oxidized to peroxodicarbonate. The team then found out that this oxidizer was strong enough to degrade stubborn Kraft lignin.

The team report that, when freshly produced, the peroxodicarbonate depolymerizes and oxidizes Kraft lignin with similar effectiveness to traditional methods. However, in a departure from these conventional methods, no environmentally harmful chemicals are used or produced in the process.

High Demand for Vanillin

The need for vanillin is high: “Most people only know of it from vanilla flavoring, but it is present in most chocolates and perfumes as well,” explains Waldvogel. Vanillin is also a precursor material for pharmaceuticals.

All these uses mean that around twenty thousand tons of vanillin are needed every year, and the vanilla plant alone cannot keep up with this demand. The first steps are being made to use Kraft lignin to meet demand. Siegfried Waldvogel and the team are already working on a pilot plant to test scaling up.

Reference

- Peroxodicarbonate as a Green Oxidizer for the Selective Degradation of Kraft Lignin into Vanillin,

Michael Zirbes, Tobias Graßl, Rieke Neuber, Siegfried R. Waldvogel,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202219217

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)

Superb work. Thank you