Polylactic acid (PLA) is a high-performance, biodegradable polymer derived from biomass. However, so far, PLA waste often cannot be broken down effectively due to the limited distribution of microorganisms that can digest it. Methods that can chemically transform post-consumer PLA into its monomeric components or other valuable small molecules would, thus, be useful to reuse waste and improve sustainability.

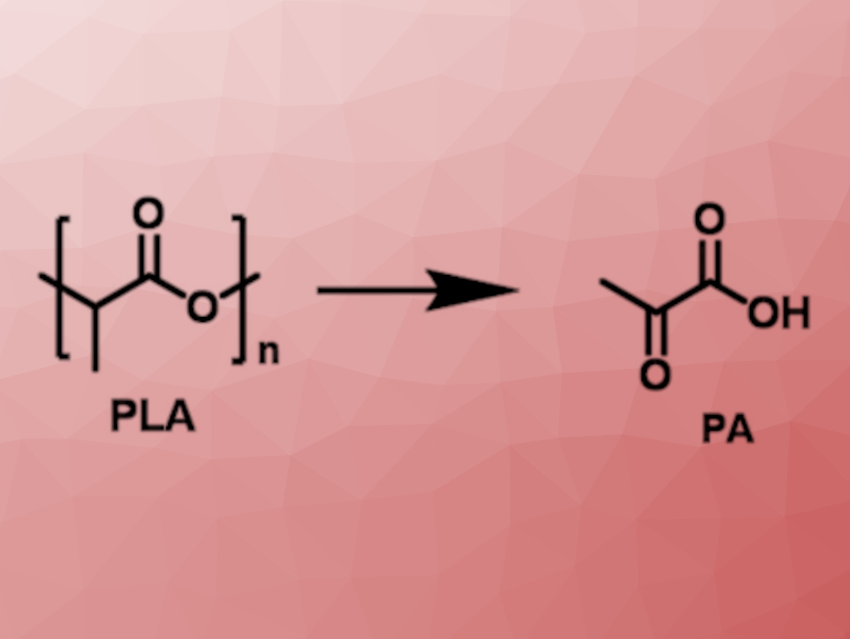

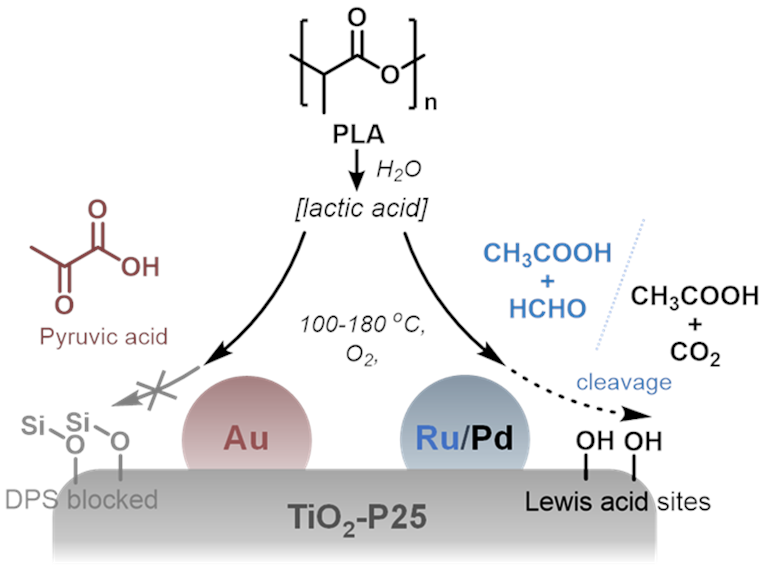

Yong Cao, Fudan University, Shanghai, China, Xinhe Bao, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, and colleagues have developed a “catalyst-controlled tandem hydrolysis-oxidation” approach to PLA waste management and recycling. The method involves the use of supported metal catalysts and molecular oxygen in water under mild reaction conditions for the efficient conversion of PLA waste into high-value chemicals (e.g., pyruvic acid, acetic acid, and formaldehyde; pictured below).

For example, a catalyst based on Au nanoparticles on TiO2 with a monolayer of diphenylsilane (DPS) groups was effective and selective for the oxidative conversion of both commercial pure PLA and PLA waste to pyruvic acid. A Ru/TiO2 catalyst gave a mixture of acetic acid and formaldehyde, and an analogous Pd-based catalyst gives acetic acid only. Overall, this method chemically upgrades PLA waste via a simple reaction process and provides access to key value-added chemical feedstocks.

- Upgrading Waste Polylactide via Catalyst‐Controlled Tandem Hydrolysis‐Oxidation,

Kaizhi Wang, Zehui Sun, Wendi Guo, Mugeng Chen, Conglin Zhu, Jiachen Fei, Yongmei Liu, Heyong He, Yong Cao, Xinhe Bao,

ChemSusChem 2023.

https://doi.org/10.1002/cssc.202301128