Lithium sulfur batteries (LSBs) are promising candidates for the replacement of lithium-ion batteries. Low-cost, high-performance, and easy-to-synthesize cathode materials for LSBs are needed. However, the practical application of LSBs is hampered by the polysulfide shuttle, i.e., the formation of soluble polysulfide species.

To solve this problem, researchers commonly use conductive ordered carbon matrices or cathodes containing sulfur covalently bound to the polymeric matrix, which allow for true solid-phase transitions. However, electrode materials based on ordered carbons often require complicated syntheses, and those containing covalently bound sulfur are very often limited to low sulfur loadings (<50 %).

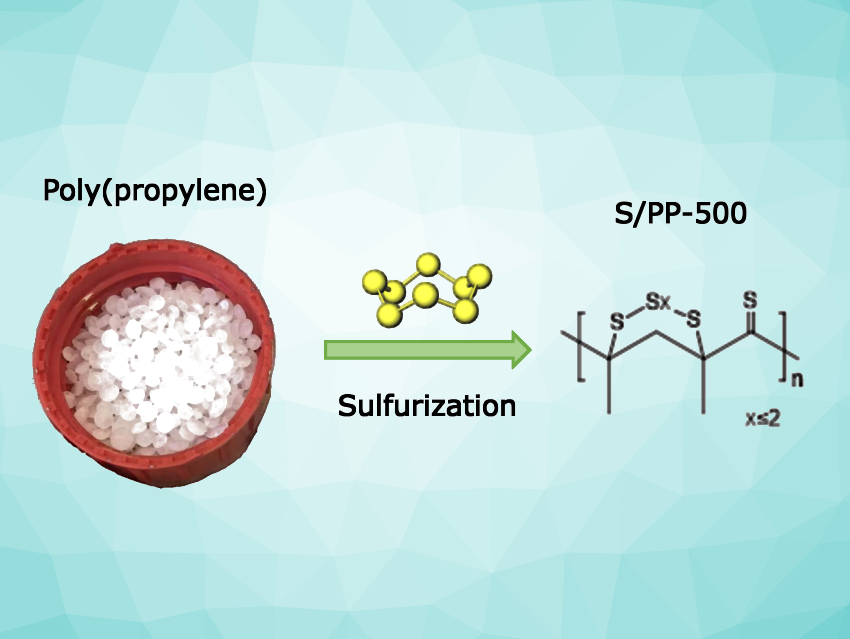

Michael Rudolf Buchmeiser, University of Stuttgart, Germany, and colleagues have prepared sulfurized polypropylene (S/PP-500) as a cathode material with up to 68 wt% sulfur loading. This loading is higher than most reported electrode materials containing covalently bound sulfur. The team reacted polypropylene with elemental sulfur at 500 °C under an N2 flow to obtain S/PP-500. During this reaction, hydrogen is removed in the form of H2S, and sulfur is chemically bound to the polymer.

The material shows only solid-phase transitions and exhibits a reversible capacity as high as 1000 mAh/gsulfur at 0.1 C and 780 mAh/gsulfur at 0.5 C, respectively. The team also observed a low capacity decay and close to 100 % Coulombic efficiency. With these properties, S/PP-500 can be regarded a promising cathode material for practical use.

- Sulfurized Polypropylene as Low‐Cost Cathode Material for High Capacity Lithium‐Sulfur Batteries,

Qian Du, Mathis Benedikter, Kathrin Küster, Tolga Acartürk, Ulrich Starke, Jean-Louis Hoslauer, Thomas Schleid, Michael Rudolf Buchmeiser,

Batteries Supercaps 2022.

https://doi.org/10.1002/batt.202200277