Due to the energy transition, demand for petroleum products will continue to decline, and demand for petrochemical feedstocks is expected to increase. This presents a double challenge for the more than 600 refineries worldwide, and many refiners are considering moving away from processing crude oil into mostly fuels and instead aiming to process crude oil into chemicals. This means that refinery design and operations need to be rethought. Since capital investment and new plant construction take time, these considerations should be made now.

According to the authors, there are three ways to increase the petrochemical yield of refinery operations:

- Modification of individual process units

This lends itself, for example, to a refinery’s workhorse, the fluid catalytic cracker (FCC). It converts vacuum gasoil (a high-density, low-value crude oil component) into more valuable products such as gasoline. FCC gasoline contains naphtha and aromatics that could be separated as petrochemical feedstocks, but few FCC plants are designed for this process. - Changing the mix of process units

The various process technologies are each designed for a different product yield: Coking, residual hydrocracking, and visbreaking eliminate residuum; FCC, isomerization, reforming, and alkylation maximize gasoline production; and hydrocracking maximizes diesel and jet fuel production. - Building plants to convert crude oil directly to chemicals

Saudi Aramco, for example, is exploring this technology, targeting 70–80 % chemicals per barrel of crude oil.

Different strategies will come into play depending on the company and regional conditions. The transition to a more circular value chain will also provide refiners with new integration opportunities. Refineries could, for example, play an important role in enabling advanced recycling of plastic waste or integrating waste gasification plants.

- From crude oil to chemicals: How refineries can adapt to shifting demand,

Tim Fitzgibbon, Theo Jan Simons, Gustaw Szarek, Sari Varpa,

McKinsey & Company June 30, 2022.

(accessed July 5, 2022)

Also of Interest

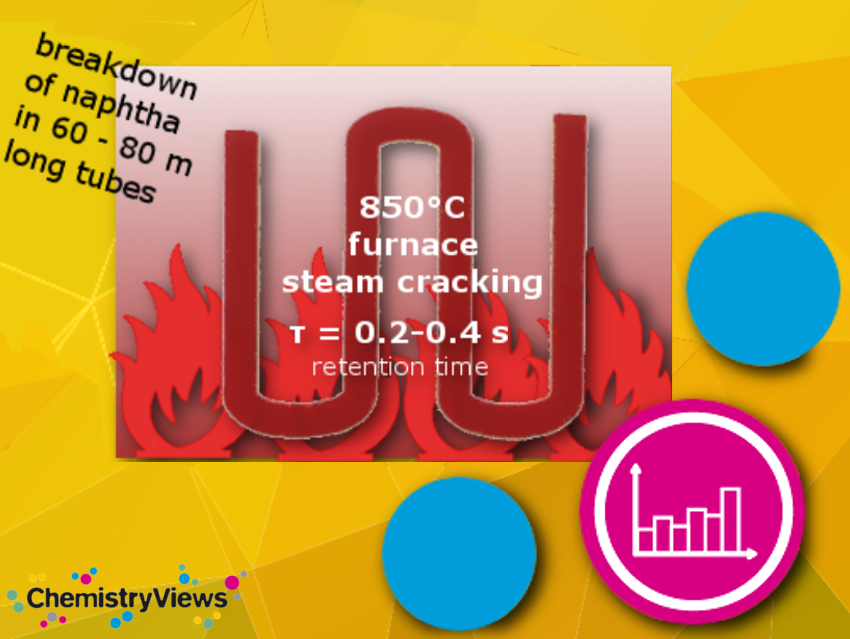

Clever Picture: Steamcracker

Learn from this picture how a steamcracker works