Polystyrene, the main material in plastic tableware and many insulating materials, is widely used but currently difficult to recycle. Guoliang Liu, Virginia Tech, Blacksburg, USA, and colleagues have developed a thermochemical approach that makes it possible to recover valuable chemicals from polystyrene waste in a simple two-step process. This new approach could enable the recycling of insulating and packaging materials for a truly circular plastics economy.

Thermochemical Degradation

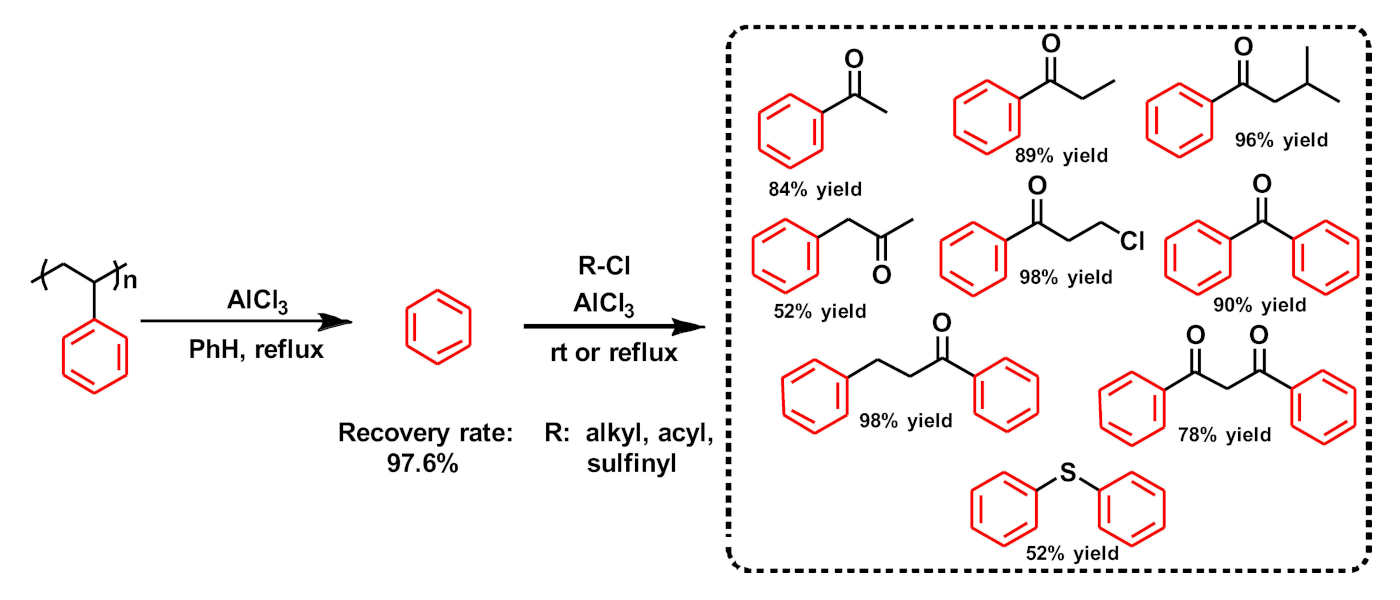

The developed “degradation upcycling” process (“Deg-Up” for short) makes it possible to produce a wide array of highly valuable aromatic chemicals from polystyrene waste. The process involves a two-step cascade: In the first step, polystyrene is broken down to give benzene as the main degradation product, and in the second step, this benzene is chemically modified in the same reactor. The process gives rise to many important substances for the cosmetics and pharmaceuticals industries.

Methods for breaking down polystyrene into benzene usually require expensive catalysts, are energy-intensive, or produce a complex mixture of products. The team’s new thermochemical method uses inexpensive aluminum chloride as the catalyst and can be performed at a moderate temperature of 80 °C. Another advantage of the method is the clever use of the solvent, benzene. “Only the amount of benzene recovered from the polymer is converted into the desired chemical. Unused solvent can be recycled to process more polymer feed,” Liu says.

Versatile Strategy

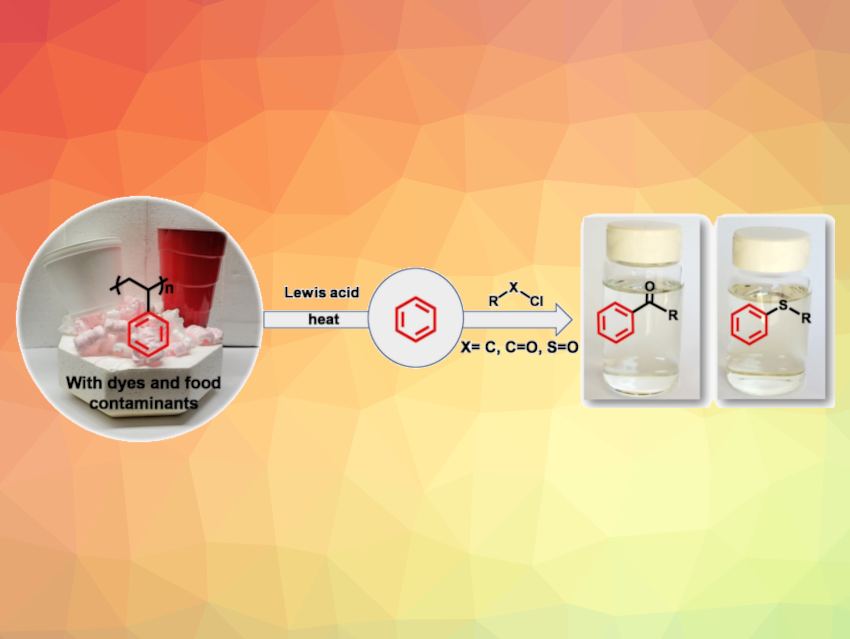

As a proof of concept, the team dissolved various types of polystyrene waste, such as packing peanuts and plastic utensils, in benzene and heated the mixture in a reactor under air-free conditions with aluminum chloride. The liquid product, consisting primarily of benzene, can be used directly to obtain the desired value-added chemicals in high yield and with high selectivity (examples pictured below). The benzene can be derivatized using a variety of acyl/alkyl and sulfinyl chloride reagents.

For example, by adding acetyl chloride, the team obtained acetophenone, an important chemical in the cosmetics and pharmaceuticals industries. By adding oxalyl chloride, the team obtained benzophenone, a common ingredient in sunscreen products and plastic additives. In addition, sulfur-containing aromatics, some of which are used as high-performance solvents in the polymer industry, were produced with a high degree of selectivity from polystyrene waste.

From Waste to Valuable Chemicals

The goal of this new chemical upcycling method is to recycle large volumes of polystyrene waste into value-added chemicals for other industrial processes. With their low density, polystyrene insulating materials are usually not well-suited to mechanical recycling, i.e., the process of sorting, shredding, and transportation of materials for the profitable manufacture of new products. Improved chemical recycling strategies could help to overcome this hurdle.

The “Deg-Up” process is robust, tolerant of contamination, and suitable as a platform for chemical upcycling of large-volume polystyrene waste. The approach is designed with an emphasis on versatility and generalizability to produce a library of high-value chemicals.

- A Generic Platform for Upcycling Polystyrene to Aryl Ketones and Organosulfur Compounds,

Nuwayo Eric Munyaneza, Carlos Posada, Zhen Xu, Vincenzo De Altin Popiolek, Griffin Paddock, Charles McKee, Guoliang Liu,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202307042

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)