A coating of solar cells with special organic molecules could pave the way for a new generation of solar panels. This coating can increase the efficiency of monolithic tandem cells made of silicon and perovskite while lowering their cost—because they are produced from industrial, microstructured, standard silicon wafers.

Improving Tandem Solar Cell Efficiency

In solar cells, light “knocks” electrons out of a semiconductor, creating positively charged “holes” and free electrons that can be collected as electrical current. Tandem cells improve solar cell efficiency by using two semiconductors to absorb different light wavelengths: silicon captures red and near-infrared light, while perovskite absorbs visible light.

Monolithic tandem cells are created by coating these two semiconductors on a single support on to of each other. For a perovskite/silicon system, this is usually achieved by using silicon wafers that are produced by the zone melting process and have a polished or nanostructured surface.

Alternatively, cheaper silicon wafers produced by the Czochralski process with micrometer-scale pyramidal structures on their surface improve light capture by reducing reflectivity. However, coating these wafers with perovskite introduces defects in the crystal lattice, which affect the electronic properties. Transfer of the released electrons is impeded, and electron-hole recombination increasingly occurs through processes that do not emit light. Both the efficiency and the stability of the perovskite layer are decreased.

Czochralski silicon is a high-purity silicon crystal grown using the Czochralski process, a method developed by Jan Czochralski. In this process, a seed crystal is dipped into molten silicon and slowly pulled out while rotating. This method produces large, single-crystal silicon ingots with a uniform structure, which are then sliced into thin wafers used in semiconductor devices and solar cells. Czochralski silicon is known for its high quality and is commonly used in the production of electronics and photovoltaic cells.

New Surface Passivation Strategy Enhances Efficiency of Perovskite/Silicon Solar Cells

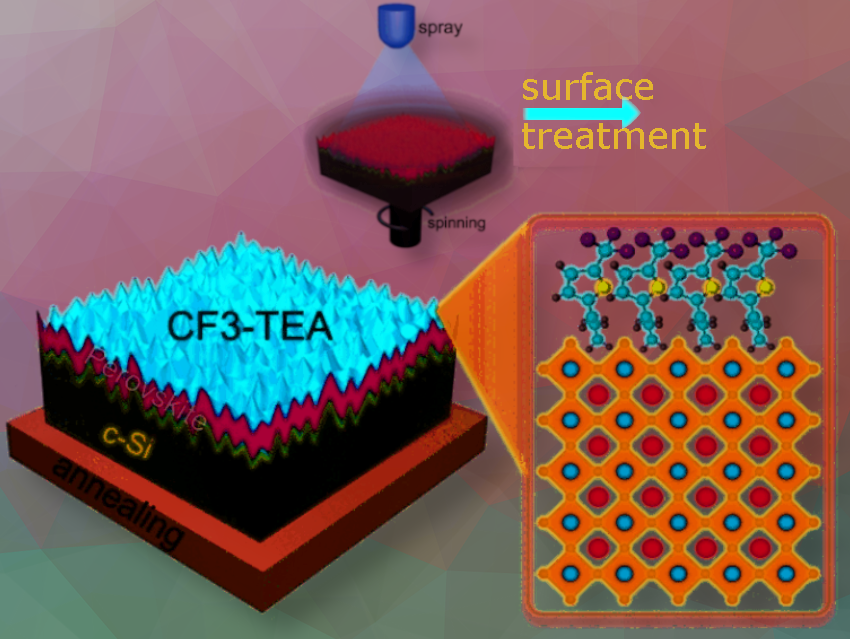

Kai Yao, Nanchang University, China, and colleagues have developed a surface passivation strategy for perovskite layers. This method allows the surface defects of the perovskite layer to be smoothed out. A thiophenethylammonium compound with a trifluoromethyl group (CF3-TEA; 2-[5-(trifluoromethyl)thiophen-2-yl]ethan-1-ammonium) is applied by a dynamic spray coating process. This forms a very uniform coat—even on microtextured surfaces.

The CF3-TEA coating effectively reduces surface defects due to its high polarity and binding energy. Nonradiative recombination is suppressed, and the electronic levels are adjusted so that the electrons at the interface can be more easily transferred to the electron-capturing layer of the solar cell. Surface modification with CF3-TEA allows perovskite/silicon tandem solar cells based on common textured wafers made of Czochralski silicon to attain a very high efficiency of nearly 31% and maintain long-term stability.

- Surface Molecular Engineering for Fully Textured Perovskite/Silicon Tandem Solar Cells,

Jun Chen, Shaofei Yang, Long Jiang, Ke Fan, Zhiliang Liu, Wentao Liu, Wei Li, Haitao Huang, Hong Zhang, Kai Yao,

Angewandte Chemie International Edition 2024.

https://doi.org/10.1002/anie.202407151