Using the bacterium Basfia succiniciproducens, BASF aims to convert sugar and carbon dioxide into fumaric acid, an important intermediate for chemical production. BASF is collaborating with Saarland University, University of Marburg, and University of Kaiserslautern-Landau, all Germany, in the FUMBIO (FUMarsäure BIObasiert) research project. Isolated in 2008 from a Holstein cow’s rumen, this bacterium will be genetically modified to produce large quantities of bio-based fumaric acid (fumarate) during fermentation. This bio-based intermediate can be used by BASF to create products with a low carbon footprint, such as food and animal feed additives, medication starting materials, and polymer and detergent building blocks.

The FUMBIO project will measure and compare the CO2 footprint of bio-based fumarate with that of petrochemical-based production. The partners expect the bio-based process to have a significantly lower carbon footprint, possibly even negative, due to CO2 use as a raw material. The CO2 for fermentation will come from exhaust gas streams at chemical production plants. Germany’s Federal Ministry for Education and Research is funding the project with around €2.6 million.

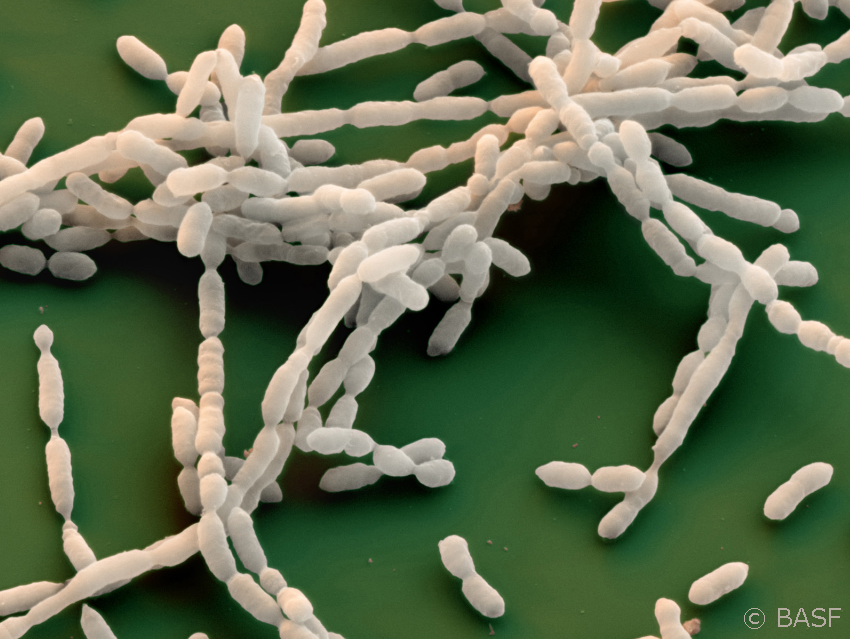

Photo: The Basfia succiniciproducens bacterium. © BASF SE

- BASF SE, Ludwigshafen, Germany