Microwave Chemical, Chiyoda Corporation, and Mitsui Chemicals have started a collaboration to develop a microwave-based naphtha cracking technology to reduce CO2 emissions compared to traditional fossil fuel-based methods. Microwave Chemical has developed what it calls M-Cracker®︎. This new concept for cracking differs from conventional methods by directly heating the reaction zone using microwaves. The M-Cracker®︎ is expected to be further improved in the near future by an advanced catalytic naphtha cracking technology developed by Chiyoda Corporation.

Microwave Chemical, which has expertise in scaling up microwave processes, Chiyoda Corporation, which has experience in designing, procuring, and building ethylene plants, and Mitsui Chemicals, which operates the longest-running ethylene plant in Japan, will work together to advance the development of this innovative approach so that it can be widely adopted. This initiative not only seeks to enhance the economic viability of ethylene plants globally but also contribute to carbon neutrality within the chemical industry.

- Microwave Chemical Co., Ltd., Suita City, Osaka Osaka, Japan

- Chiyoda Corporation, Yokohama City, Japan

- Mitsui Chemicals, Inc., Chuo-ku, Tokyo, Japan

Also of Interest

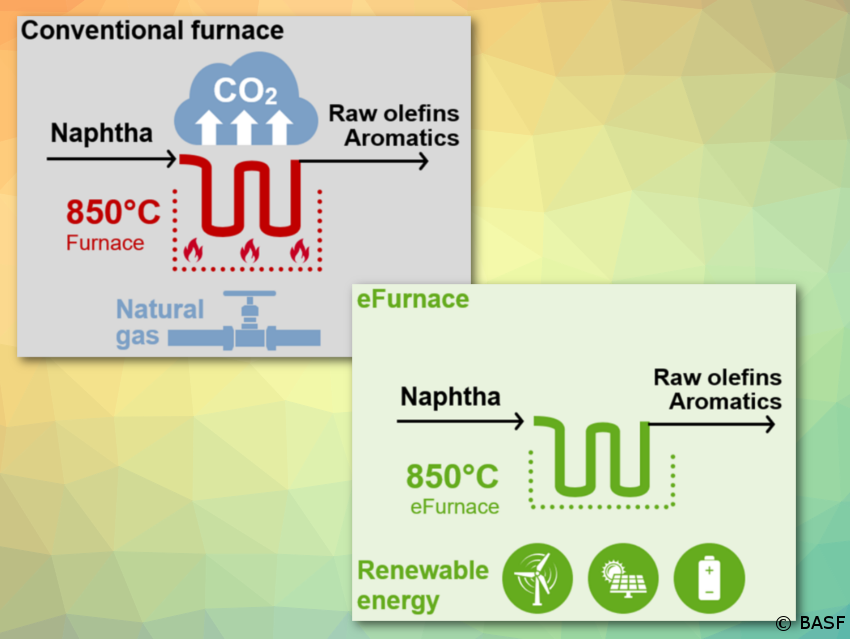

First Electrically Heated Steam Cracker

BASF, SABIC, and Linde join forces to demonstrate innovative concept to reduce CO2 emissions