Carbohydrates are an abundant, inexpensive, and renewable biomass feedstock that could be a cornerstone for sustainable chemical manufacturing. However, scalable and environmentally friendly methods to use these feedstocks are limited.

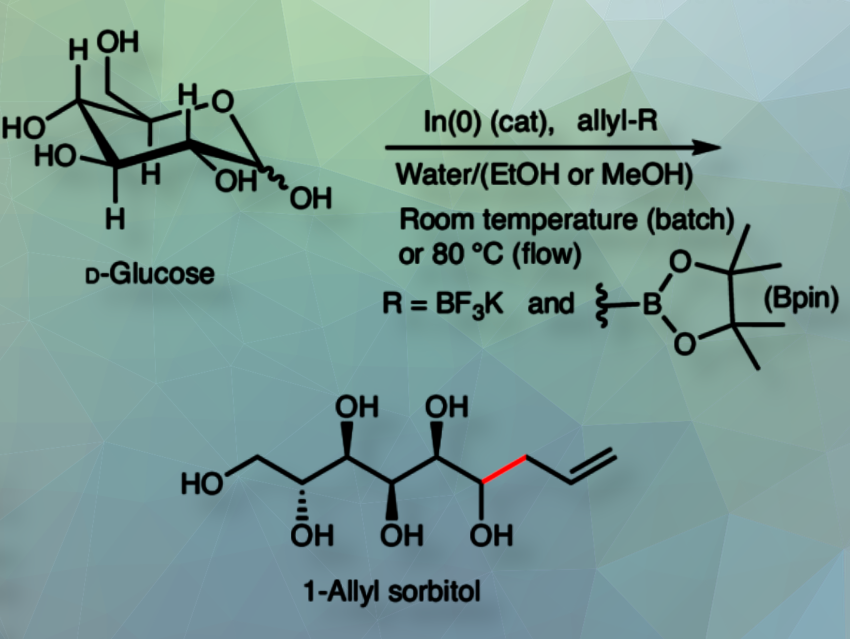

Klavs F. Jensen, Massachusetts Institute of Technology (MIT), Cambridge, MA, USA, Scott E. Denmark, University of Illinois at Urbana-Champaign, USA, and colleagues have developed a sustainable catalytic method for allylating unprotected carbohydrates in water to produce 1-allyl sorbitol, a crucial precursor to Millad NX 8000. This widely used additive makes polypropylene plastics more transparent and more heat-resistant. The team used recyclable indium metal as a catalyst and benign boron-based reagents, either allylboronic acid or its pinacol ester (allylBpin), as donors.

Using this water-based catalytic process, the researchers achieved high-yield allylation of aldohexoses, aminohexoses, ketohexoses, and aldopentoses under mild conditions. The process was further optimized with machine learning to enable continuous flow synthesis, making it suitable for industrial applications. The reusability of the indium metal catalyst and benign nature of the allylboron reagent will greatly improve the existing manufacturing process that employs allyl bromide and stoichiometric amounts of tin metal which create a toxic waste stream.

Given the projected rise in global demand for clarified polypropylene—to over 5 million metric tons by 2030 (corresponding to 40,000 metric tons of Millad NX-8000)—this innovation may significantly reduce the environmental impact of a widely used material, the researchers say.

- Catalytic allylation of native hexoses and pentoses in water with indium,

Tapas Adak, Travis Menard, Matthew Albritton, Federico Florit, Martin D. Burke, Klavs F. Jensen, Scott E. Denmark,

Nature 2025.

https://doi.org/10.1038/s41586-025-08690-z