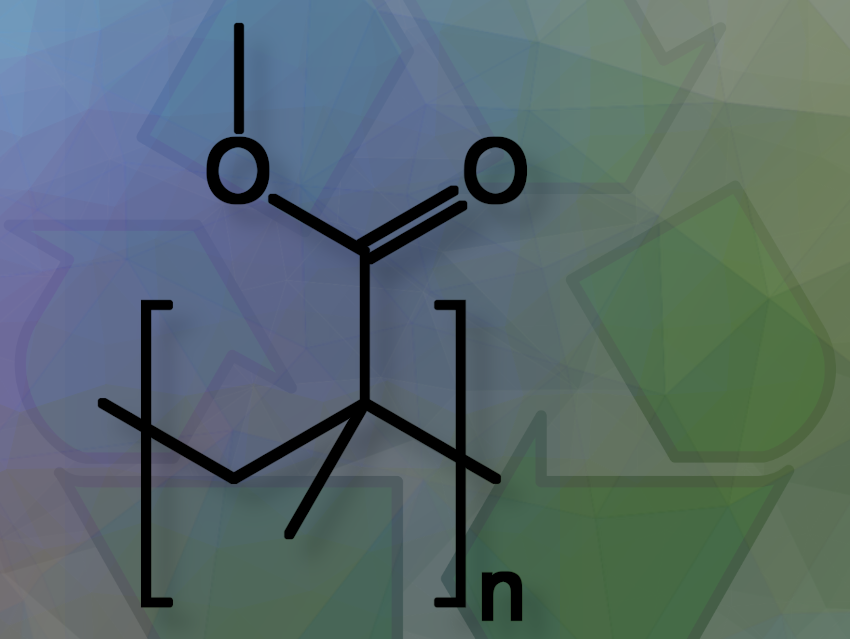

Röhm and POLYVANTIS, in collaboration with Pekutherm and NEXTCHEM have launched a Europe-wide alliance to advance the recycling of polymethyl methacrylate (PMMA). So far, the greatest challenges of the circular economy have been the lack of infrastructure, logistics, and the availability of economically viable and sufficient quantities of recyclable PMMA. Thanks to the partnership, considerably more PMMA materials can now be processed through both mechanical and chemical recycling and returned to the market as methyl methacrylate (MMA), and PMMA in virgin-like quality. The network is interested in cooperating with all PMMA processing companies in Europe.

Pekutherm collects recyclable materials and offers PMMA processing companies across Europe with customized concepts for plastic waste disposal. The company ensures that the collected scrap and waste are separated by type, pass through a multi-step sorting process, and are granulated in a defined geometry. This is done both for post-industrial recyclable materials—which is crucial for significantly increasing recycling rates—and post-consumer plastic waste. As the largest company in Europe specialized in PMMA recycling, Pekutherm has a sorting capacity of 10,000 tons per year.

The sorted PMMA is then delivered to Röhm and POLYVANTIS, where it is reused as raw material in production after just one additional processing step.

MyRemono, NEXTCHEM’s subsidiary specializing in plastics recycling, processes PMMA unsuitable for mechanical recycling. Using their advanced NXRe™ technology, a molten metal depolymerization process, MyRemono chemically converts this PMMA back into pure MMA. This continuous process for recycling plastic waste is being brought to industrial scale in Italy with support from the EU Innovation Fund. The new plant, expected to be operational by 2026, will have an initial processing capacity of 5,000 tons of PMMA per year. According to the companies, the recycled MMA will achieve a carbon footprint reduction of over 90 %, avoiding approximately 13,000 tons of greenhouse gas emissions annually at full capacity.

Röhm markets low-carbon products under its proTerra brand, using recycled PMMA, methyl methacrylate (MMA), or ISCC-PLUS (International Sustainability and Carbon Certification PLUS)-certified sustainable raw materials.

- NEXTCHEM, Rome, Italy

- Pekutherm, Geisenheim, Germany

- POLYVANTIS, Weiterstadt, Germany

- Röhm, Darmstadt, Germany

Also of Interest

Chemolysis and pyrolysis are promising processes for cases in which mechanical recycling is not effective—an introduction and examples from Covestro