Biologically engineering yeast strains to produce industrially important chemicals is a significant area of research with the aim, among others, of allowing the chemical industry to become less reliant on fossil resources. However, most yeasts can only be engineered to work efficiently with one substrate, greatly limiting their utility.

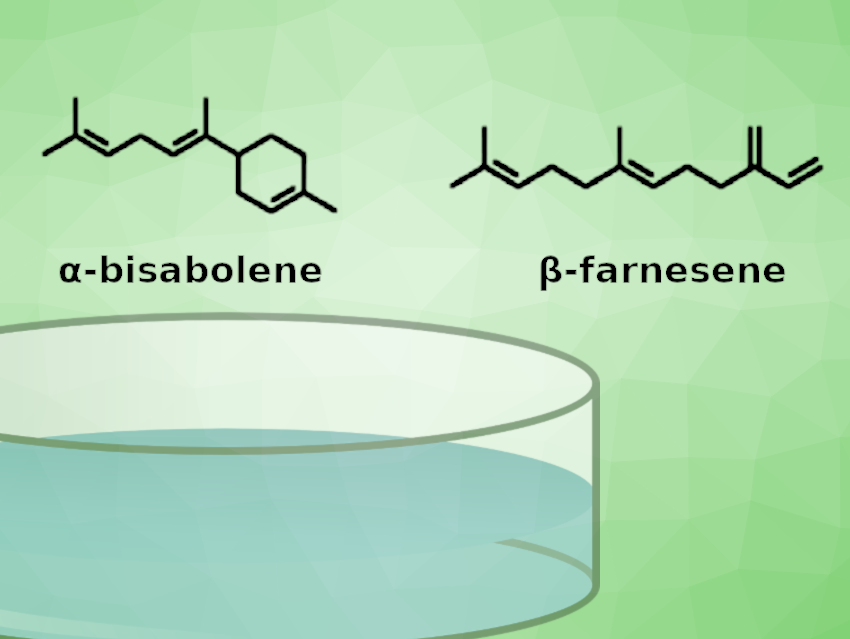

Peng Cai, Yongjin J. Zhou, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, and colleagues have succeeded in producing a strain of the yeast Pichia pastoris (reclassified as Komagataella phaffi) which can use either methanol or glucose as a substrate and can produce α-bisabolene or β-farnesene, both important sesquiterpenes.

Producing Sesquiterpenes

Sesquiterpenes constitute a class of compounds that have a variety of uses in industry. Bisabolenes, for example, are used in fragrances for their balsamic notes, and also have potential as diesel precursors and as a cold-weather fuel additive. Farnesene, another sesquiterpene, is used in vitamin E production and is also being investigated as a replacement jet fuel that can be produced from renewable resources.

Producing sesquiterpenes is a major challenge for chemists. At present, conventional yeast strains such as Saccharomyces cerevisiae (brewer’s or baker’s yeast) are engineered to produce sesquiterpenes from glucose. However, there is a need for more diverse substrates to feed the yeasts, given that sources of glucose are in increasing demand to feed the ever-growing human population.

Methanol represents another carbon source that is of great interest, especially as it can be obtained from CO2 and solar energy. This makes it sustainable, and it could even potentially be coupled to carbon sequestration from the atmosphere.

The Mevalonate Pathway

Many plants and fungi use the mevalonate (MVA) metabolic pathway to produce sesquiterpenes or terpenoids from various carbon sources, including methanol and glucose, via acetyl-CoA (acetyl coenzyme A). The team used two genes for enzymes that are part of the MVA pathway, a bisabolene synthase for producing α-bisabolene from the grand fir (Abies grandis), and a farnesene synthase for producing β-farnesene from sweet wormwood (Artemisia annua). They inserted these genes, using plasmids and CRISPR/Cas9 technology, into the yeast P. pastoris.

The two enzyme-encoding genes were tested individually in the engineered yeasts, showing that P. pastoris can be modified relatively straightforwardly to produce either of these sesquiterpenes (pictured above) from methanol or glucose.

The Importance of Constitutive Promoters

Genes cannot be expressed as proteins simply by themselves and need promoters, which are segments of DNA, usually upstream of the gene in question, that call a cell’s “attention” to a gene that is to be expressed and help to bring the relevant machinery into the right position. The team, therefore, added constitutive promoters (gene promoters that are always active in a cell, rather than ones requiring a signal to switch on) for both of the enzyme-encoding genes to the P. pastoris strains. The constitutive promoters are also key to enabling the yeasts to use more than one source of carbon, since genes will be expressed consistently, rather than being based on levels of the methanol or glucose molecules themselves (so-called methanol/glucose-inducible promoters).

When cultivating their engineered yeast strains on substrates containing either methanol or glucose, the team found that the yeasts were capable of using both of these carbon sources to produce the sesquiterpenes of interest in good yields. The team, thus, succeeded in producing a versatile platform for sesquiterpene production, paving the way for a more sustainable and flexible production of important chemicals.

- Engineering a versatile yeast platform for sesquiterpene production from glucose or methanol,

Linhui Gao, Kun Zhang, Yiwei Shen, Peng Cai, Yongjin J. Zhou,

Biotechnol. J. 2024.

https://doi.org/10.1002/biot.202400261