Lithium-ion batteries are extremely common in portable electronics, and improving their capacity and stability is an important goal in energy storage research. Silicon is a promising anode material due to its extremely high theoretical capacity. However, it suffers large volume changes during lithiation/delithiation cycles, which limits the electrode’s stability.

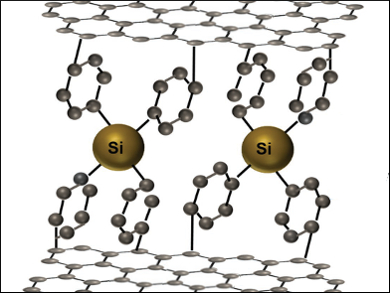

Yong‐Mook Kang and colleagues, Dongguk University, Seoul, Republic of Korea, have developed a highly conductive and mechanically robust silicon-based anode material for lithium-ion batteries. The team coated commercially available silicon nanoparticles with polydopamine by mixing them with dopamine hydrochloride in a Tris-buffer solution (Tris = tris(hydroxymethyl)aminomethane) and stirring for 24 hours. They then “sandwiched” the coated nanoparticles between layers of graphene oxide (GO). They built a three-layered structure by consecutively filtering solutions/dispersions of GO, the nanoparticles, and GO again. The obtained sandwich structure (pictured) was calcined at 700 °C for two hours under a hydrogen/argon atmosphere. This step converts the graphene oxide to reduced graphene oxide (rGO).

According to the researchers, the polydopamine layer forms strong bonds with rGO and anchors the silicon nanoparticles on the rGO layers. This prevents the nanoparticles from aggregation and from losing electrical contact. The flexibility of the sandwich structure limits volume changes during charge/discharge cycles and thus helps to avoid mechanical damage and improves the stability of the anode. The material has a high capacity and a long cycle life (about 93 % capacity retained after 400 cycles).

- Carbon-Coated Si Nanoparticles Anchored between Reduced Graphene Oxides as an Extremely Reversible Anode Material for High Energy-Density Li-Ion Battery,

Daniel Adjei Agyeman, Kyeongse Song, Gi-Hyeok Lee, Mihui Park, Yong-Mook Kang,

Adv. Energy Mater. 2016.

DOI: 10.1002/aenm.201600904