Janus particles, which have two faces with differing properties, have been used as emulsifiers, as biomedical imaging agents, in electronic displays, and in other applications. Making self-supporting two-dimensional Janus films is difficult, however: the different functional groups tend to aggregate and form micelles.

Yara Ghoussoub and Joseph Schlenoff, Florida State University, Tallahassee, USA, produced Janus films by stacking 39 alternating layers of the hydrophilic components poly(diallyldimethylammonium), PDADMA, and poly(styrenesulfonate), PSS, on a solid substrate, with PDADMA layers on the top and bottom of the stack.

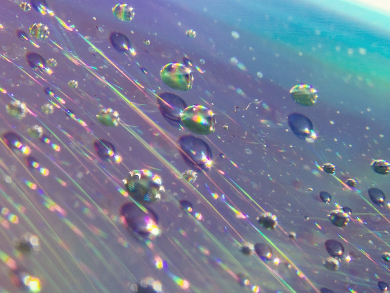

They coated the free surface with Nafion, a hydrophobic perfluorinated anionic polyelectrolyte, and they used a dilute alkaline solution to release the films from the substrate. Water contact angles were 94 degrees for the hydrophobic Nafion-coated surface and 34 degrees for the hydrophilic surface.

In addition to providing a hydrophobic surface, the Nafion coating protected the film’s structure, preserving the layers for as long as 15 hours in a 2.5 M KBr solution. Films at least 400 nm thick were stiff enough to prevent self-association of the hydrophobic regions in salt solutions, but films thinned by treatment with salt solution folded spontaneously.

- Janus Nanofilms,

Yara E. Ghoussoub, Joseph B. Schlenoff,

Langmuir 2016, 32, 3623–3629.

DOI: 10.1021/acs.langmuir.6b00672