Oil foams could have numerous uses in the food and cosmetic industries, but they are difficult to produce. The surfactants that act as stabilizing agents in aqueous foams are inefficient at reducing tension at oil-air interfaces.

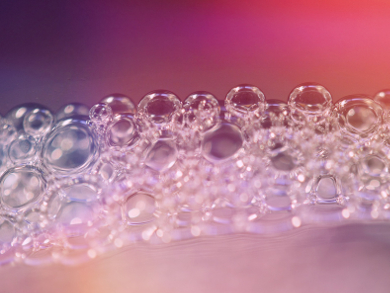

Anne-Laure Fameau, L’Institut National de la Recherche Agronomique (INRA), Nantes, France, Arnaud Saint-Jalmes, Université de Rennes, France, and colleagues reported a simple method of making oil foams, from viscous liquids to strong gels, using mixtures of sunflower oil and fatty alcohols. Fatty alcohol crystal platelets surround and stabilize the air bubbles within the foam. These foams can remain stable for months as long as the temperature stays below the melting point of the crystals.

This stability is not affected by the fatty alcohol chain length and concentration below the crystals’ melting point; however, these factors do affect the temperature at which the crystals melt. Raising the temperature causes the foams to begin to disintegrate, and lowering the temperature halts the process. Adding UV absorbers like carbon black particles makes it possible to collapse specific regions of the foam by focusing light on those regions. Foam disintegration stops immediately when the UV source is removed.

- Smart Nonaqueous Foams from Lipid-Based Oleogel,

Anne-Laure Fameau, Stephanie Lam, Audrey Arnould, Cédric Gaillard, Orlin D. Velev, Arnaud Saint-Jalmes,

Langmuir 2015.

DOI: 10.1021/acs.langmuir.5b03660