During fracking operations, foam is injected into an extraction site to plug side pores and keep the oil flowing in the main recovery channel. This also helps prevent water from contaminating the recovered oil. Polymers form stable foams; however, their viscosity makes it difficult to force them into small pores. Polymer foams become less viscous and eventually break down at temperatures higher than 85 °C. Gel-enhanced polymer foams overcome many of these problems, providing effective plugging and stability.

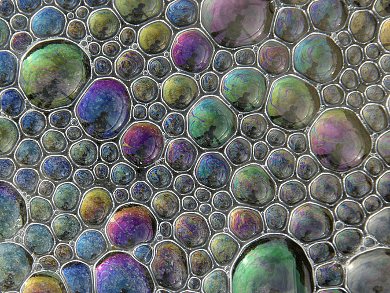

Guang Zhao and colleagues, China University of Petroleum, Qingdao, evaluated the performance of foams enhanced with comb-polymer gels in high-temperature reservoirs using laboratory experiments and oilfield tests. Comb-polymer gels form viscoelastic shells around foam bubbles, protecting them against shrinkage and drainage and improving their stability. The comb polymer gel increases the solution viscosity, but decreases its surface tension. This reduces the foam volume but increases the thickness and strength of the film.

Oilfield tests in high-temperature reservoirs (100 °C) showed that the gel-enhanced foam increased oil production and decreased water contamination.

- Enhanced foam stability by adding comb polymer gel for in-depth profile control in high temperature reservoirs,

Guang Zhao, Caili Dai, Yanhui Zhang, Ang Chen, Zhihu Yan, Mingwei Zhao,

Colloids Surf., A 2015, 482, 115–124.

DOI: 10.1016/j.colsurfa.2015.04.041