Graphene 3D Lab, Calverton, NY, USA, produced a graphene nanocomposite filament for typical 3D printers. However, most of the desirable properties of graphene, such as strength and weight, are lost with this approach since the graphene has to be mixed with a thermoplastic material to make printing possible. Only conductivity remains.

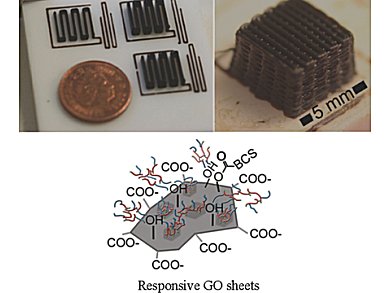

Esther García-Tuñon, Imperial College London (ICL), UK, and colleagues have designed a method to 3D print pure graphene structures. They use a graphene oxide paste consisting of graphene oxide along with a responsive polymer. The formulations have the flow and physical properties needed for the filament deposition process required in 3D printing: They flow through very small nozzles and set immediately after passing through them, and retain the shape. Once the print is completed, drying and thermal reduction leads to ultra-light graphene-only structures with restored conductivity and elastomeric behavior.

The researchers want to scale up this process and create new formulas for a variety of possible applications from oil absorption to flexible electronics. They think that as soon as commercial graphene printing becomes possible, many industries may be substantially transformed, including areas within solar energy, aerospace, and electronics.

- Printing in Three Dimensions with Graphene,

Esther García-Tuñon, Suelen Barg, Jaime Franco, Robert Bell, Salvador Eslava, Eleonora D’Elia, Robert Christopher Maher, Francisco Guitian, Eduardo Saiz,

Adv. Mat. 2015.

DOI: 10.1002/adma.201405046