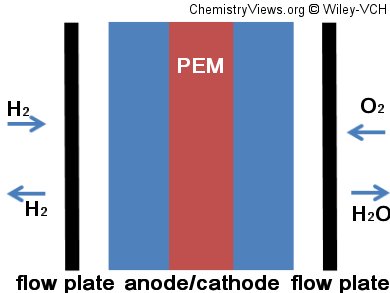

Lee Cronin and colleagues, University of Glasgow, UK, used 3D printing to produce flow plates which channel liquid reagents and gaseous products in fuel cells. Usually flow plates are made of graphite, titanium, or stainless steel. Cronin’s team used polypropylene coated with silver.

This allowed the team to construct a low-cost and light weight proton exchange membrane (PEM) electrolyzer. It showed excellent performance for a first generation device to electrolyze water in terms of efficiency, internal resistances, and current-voltage response.

- 3D Printed Flow Plates for the Electrolysis of Water: an Economic and Adaptable Approach to Device Manufacture,

Lee Cronin, Greig Chisholm, Philip Kitson, Niall Kirkaldy, Leanne Bloor,

Energy Environ. Sci. 2014.

DOI: 10.1039/C4EE01426J