Oh-Sun Kwon and Kwanwoo Shin, Sogang University, Seoul, Republic of Korea, and colleagues have fabricated a paper-based fluidic chip, or active paper open chip (APOC), that allows the full range of fluidic operations by implementing an electric input on the paper via an electrowetting technique.

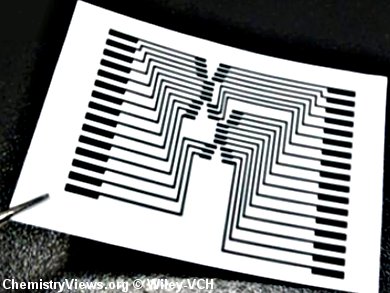

To produce a continuous flow of a liquid sample, typically the passive capillary force on the pulp in the paper is used. In their active, paper-based, microfluidic chip, the researchers used inkjet printed electrodes to transport a single, discrete drop, or a group of digital liquid drops along programmed trajectories. The patterned electrodes were designed on a desktop computer and were printed on the paper with conductive carbon nanotube (CNT) ink by using an office inkjet printer. This simple design and fabrication process can save time and significantly reduces costs.

The team found that tuning the surface tension by using lubricating silicone oil and an alternating current (AC) driving voltage at a low frequency helped to overcome the technical obstacles posed by low printing resolution and enabled various lab-on-chip (LOC) operations, such as transporting, merging and mixing, to be realized for a prototype APOC chip.

According to the researchers, this technique can be extended to develop various active devices, such as paper batteries, electric paper, and various bioassays, e.g., for matrix-assisted light deposition/ionization (MALDI) and enzyme-linked immunosorbent assay (ELISA) devices, based on flexible, disposable, and conductive paper substrates.

- Active Digital Microfluidic Paper Chips with Inkjet-Printed Patterned Electrodes,

Hyojin Ko, Jumi Lee, Yongjun Kim, Byeongno Lee, Chan-Hee Jung, Jae-Hak Choi, Oh-Sun Kwon, Kwanwoo Shin,

Adv. Mat. 2014.

DOI: 10.1002/adma.201305014