To make solid-state dye-sensitized solar cells (DSSCs), or thin-film solar cells, a sintering process that reaches temperatures of 450 °C, is used. Therefore, the cells are fabricated to stiff glass, which can withstand these temperatures.

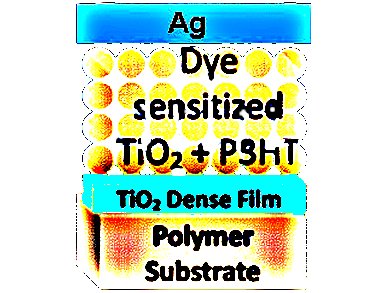

Bin Liu, National University of Singapore, and colleagues have made solid-state DSSCs on flexible plastic by developing a method that works at less than 150 °C. Atomic layer deposition (ALD) was used to create a dense TiO2 layer and a mesoporous TiO2 layer was made by electrophoretic deposition (EPD). The dense film blocks electron flow in one direction and by this ensures that the electrons move toward the correct electrode. The mesoporous film contains the flexible conducting polymer and the dye molecules.

The resulting flexible solid-state DSSCs on polymer substrates have a 1.9 % efficiency rate for sunlight-to-electricity conversion, compared to 15 % for other solid-state DSSCs. Future research focusses on finding new materials that can improve efficiency by increasing the conductance of the films of the solar cells.

- Fabrication of Flexible Plastic Solid-State Dye-Sensitized Solar Cells Using Low Temperature Techniques,

Zhaosheng Xue, Changyun Jiang, Long Wang, Wei Liu, Bin Liu,

J. Phys. Chem. C 2013.

DOI: 10.1021/jp408663d