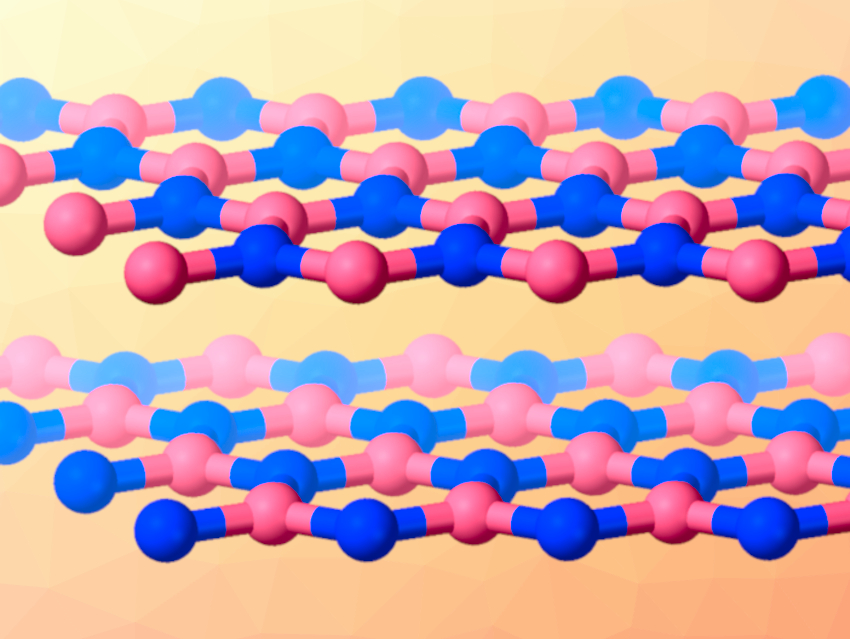

Hexagonal boron nitride (hBN, pictured) is structurally similar to graphite. It has strong covalent bonds and is chemically fairly inert. This makes it difficult to functionalize the material. Introducing defects into the structure of hBN could help to overcome this difficulty. However, this usually requires energy-intensive methods using plasma or time-consuming ball-milling.

Jose L. Mendoza-Cortes, Michigan State University, East Lansing, USA, Mauricio Terrones, The Pennsylvania State University, University Park, USA, and Shinshu University, Nagano, Japan, and colleagues have used a scalable ball-milling process in a cryogenic environment, or “cryomilling”, using liquid nitrogen to selectively and efficiently introduce defects in hBN. In this approach, the milling time can be reduced down to minutes, depending on the desired level of defects. The team used X-ray diffraction to monitor the structural changes during cryomilling.

The researchers found that cryomilling not only reduced the particle size, but also introduced defects such as hydroxyl groups and free radicals into the structure of hBN. The free-radical sites can react with metal cations to form single metal atoms or nanoclusters (e.g., with Pt, Au, Ag, Fe, or Cu) on the surface of the boron nitride. The resulting materials could be useful for catalysis. The team used boron nitride functionalized with bi-metallic AgPt nanoclusters as a catalyst for the hydrogen evolution reaction.

- Low temperature activation of inert hexagonal boron nitride for metal deposition and single atom catalysis,

Yu Lei, Srimanta Pakhira, Kazunori Fujisawa, He Liu, Cynthia Guerrero-Bermea, Tianyi Zhang, Archi Dasgupta, Luis M. Martinez, Srinivasa Rao Singamaneni, Ke Wang, Jeff Shallenberger, Ana Laura Elías, Rodolfo Cruz-Silva, Morinobu Endo, Jose L. Mendoza-Cortes, Mauricio Terrones,

Mater. Today 2021.

https://doi.org/10.1016/j.mattod.2021.09.017