Plastic waste is an important environmental problem. This issue can be tackled, e.g., with mechanical recycling or the use of biodegradable polymers. However, these methods are not suitable for all applications. The chemical recycling of polymers can be an alternative. In this approach, the material is depolymerized to obtain its monomers, which can then be reused. To allow for an economical depolymerization while providing a stable polymer material, suitable monomers have to be found.

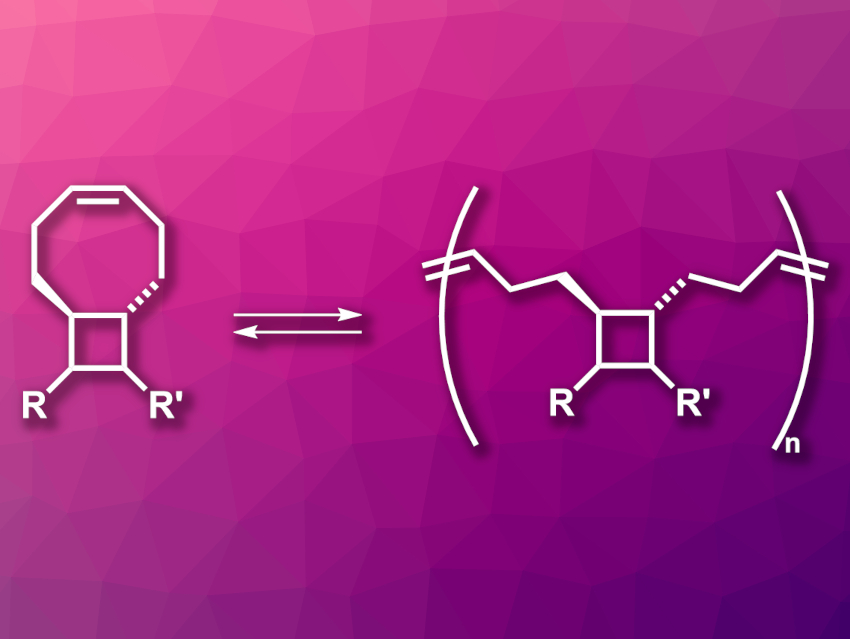

Junpeng Wang, University of Akron, OH, USA, and colleagues have developed thermally stable chemically recyclable polymers with tunable mechanical properties using cyclooctene fused with trans-cyclobutanes as the monomers (pictured). These monomers can be polymerized via ring-opening metathesis polymerization (ROMP). Usually, polycyclooctene is not chemically recyclable. However, the trans-cyclobutane ring at the 5 and 6 positions reduces the strain in the cyclooctene ring, which stabilizes the ring-fused monomer compared with “naked” cyclooctene and makes the depolymerization possible.

The fused-ring monomers can be obtained via a [2+2] cycloaddition of 1,5-cyclooctadiene and different olefins. This allows the introduction of a wide range of substituents at the cyclobutane ring of the monomers. Thus, the properties of the resulting polymers can be tuned. According to the researchers, the concept of controlling ring strain using an additional ring could also be useful for other areas of chemistry.

- Olefin metathesis-based chemically recyclable polymers enabled by fused-ring monomers,

Devavrat Sathe, Junfeng Zhou, Hanlin Chen, Hsin-Wei Su, Wei Xie, Tze-Gang Hsu, Briana R. Schrage, Travis Smith, Christopher J. Ziegler, Junpeng Wang,

Nat. Chem. 2021.

https://doi.org/10.1038/s41557-021-00748-5

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)