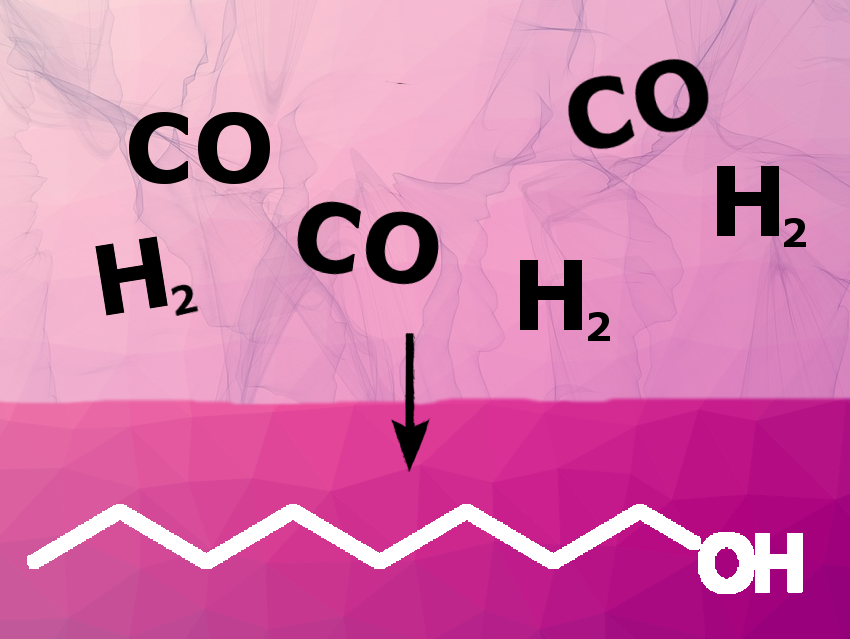

LanzaTech and BASF want to convert carbon from industrial off-gases into valuable chemicals. The partners have achieved the first success: Using special bacteria, they were able to produce n-octanol at a laboratory scale from carbon monoxide and hydrogen. These are the main components of waste gases, e.g., from the steel industry. n-octanol is, for example, used in cosmetics.

In this collaboration, biologists, biochemists, and engineers work together. LanzaTech contributes its innovative gas fermentation technology, BASF its expertise in the development and operation of chemical processes. LanzaTech’s gas fermentation technology will be integrated into the BASF Verbund. LanzaTech’s technology is already being used on a commercial scale to convert waste gases from steel production into ethanol.

The basis for the new process to produce high-value chemicals such as n-octanol through gas fermentation was developed by Ramon Gonzalez, University of South Florida, Tampa, USA. Within a few months, the two companies have developed a suitable bacterial strain for production and designed a process concept that enables continuous product generation and processing. In the next step, they plan to optimize the biology and technology design to make the production process more efficient.

The microorganisms are tolerant to the exhaust gas composition as well as to many different impurities. Therefore, no costly steps are required to purify the exhaust gas. The technology can also use a variety of feedstocks and can recycle solid waste carbon from household or agricultural waste.

Correction (May 13, 2021)

The picture originally showed H instead of H2