BASF, SABIC, and Linde have signed a joint agreement to develop and demonstrate solutions for electrically heated steam cracker furnaces. The partners have been working together on concepts to use renewable electricity instead of the fossil fuel gas typically used for the heating process.

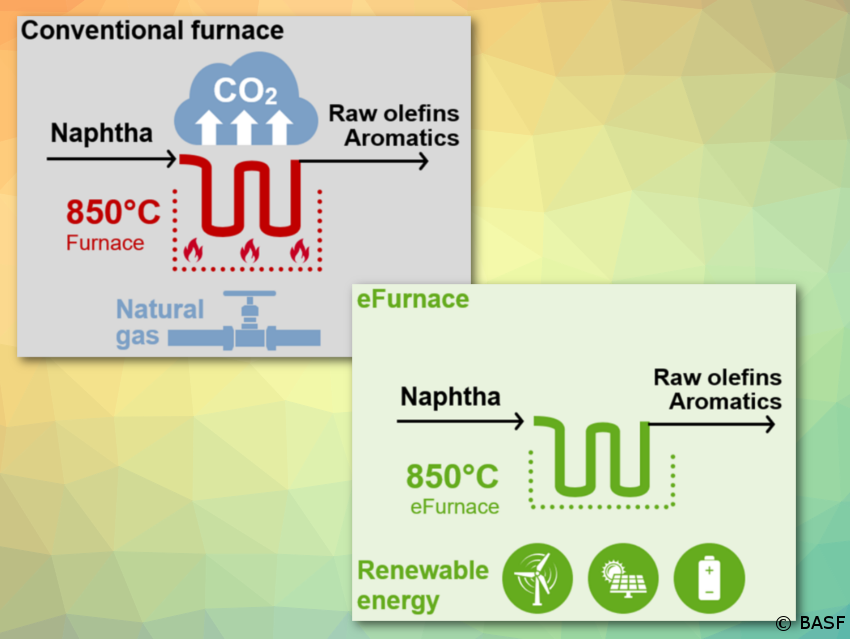

Steam crackers play a central role in the production of basic chemicals. They thermally break down a feedstock such as naphtha into olefins, for example, ethylene and propylene, and aromatics for further processing. Ethylene and propylene are the most important raw materials in the chemical industry. For this, a temperature of 850 °C must be reached. Currently, this is done by burning fossil fuels. If this energy could instead come from renewable electricity, CO2 emissions could be reduced by as much as 90 %.

The partners have applied for financial support from the EU Innovation Fund and the funding program Decarbonization in Industry (a new program of the German Federal Ministry for the Environment). The parties are looking into the construction of a multi-megawatt demonstration plant at BASF’s Ludwigshafen site in Germany, which is expected to come on stream as early as 2023, subject to a positive funding decision. Investment support and competitive prices for renewable energies are important prerequisites for being able to drive forward the timely scale-up and industrial implementation of this technology.

Also of Interest

|

Clever Picture: Steamcracker |

|

BASF – Working Intensely on Eco-Efficiency (see 1. Greening Up Steam Crackers) |