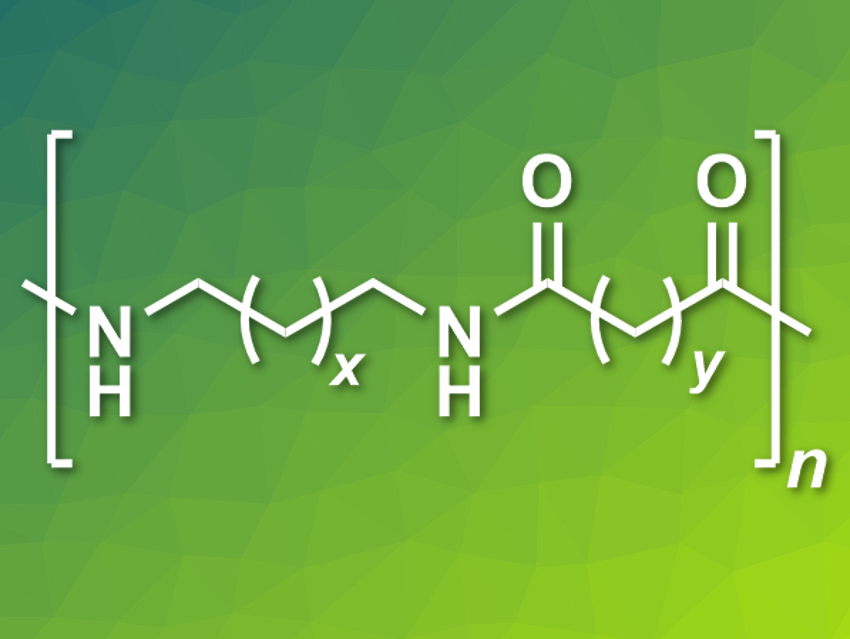

Recycling polymer waste is important to reduce the environmental impact of these materials, as well as the use of non-renewable resources. Mechanical recycling, i.e., melting down plastic waste and reusing it for new products, has its limits. After a certain number of cycles, the quality of the material degrades and prevents further reuse. Chemical recycling can solve this issue; here, the polymer is converted into its monomers, which can then be used to make new materials. Polyamides (PAs), for example, are commonly used polymers, but their chemical recycling usually requires harsh conditions and long reaction times, which can make the process uneconomic.

Urška Češarek, David Pahovnik, and Ema Žagar, National Institute of Chemistry, Ljubljana, Slovenia, have developed a simple, efficient chemical recycling process for the conversion of aliphatic polyamides into their constituent monomers. The team used PAs prepared from dicarboxylic acids and diamines (PA 66 and PA 1010) or long-chain amino acid monomers (PA 11 and PA 12) and hydrolyzed them under microwave irradiation in the presence of HCl as an acid catalyst.

They found that the PAs are rapidly and completely depolymerized under these conditions, without the formation of side products. The process still works in the presence of reinforcing additives such as glass- or carbon fibers. The monomers can be recovered in high yields and in a quality that is comparable to “new”, commercial-grade materials.

- Chemical Recycling of Aliphatic Polyamides by Microwave-Assisted Hydrolysis for Efficient Monomer Recovery,

Urška Češarek, David Pahovnik, Ema Žagar,

ACS Sustainable Chem. Eng. 2020.

https://doi.org/10.1021/acssuschemeng.0c05706

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)