3D Printing allows the manufacture of complex shapes, which is useful in a wide variety of fields, from engineering to medicine and art. Light-driven 3D printing, which converts liquid resins into solid objects via photocuring, generally provides fast build speeds and high resolutions. However, the high-energy ultraviolet (UV) light used in most 3D printers can damage the materials, which limits the method’s scope. Photocuring with less harsh visible light can solve this problem and requires less energy, but is slower.

Zachariah A. Page, The University of Texas at Austin, USA, and colleagues have developed photopolymer resins that boost the speed of visible-light curing. The researchers prepared colored resins that contain a monomer, a photoredox catalyst (PRC), combined iodonium (donor) and borate (acceptor) coinitiators, and an opaquing agent. When the PRC absorbs visible light from LEDs, it catalyzes the transfer of electrons between the co-initiators, which generates radicals that cause the monomer to polymerize. The team used zinc tetraphenylporphyrin (ZnTPP) to absorb red light, rose bengal (a fluorescein derivative) to absorb green light, the photoinitiator H-Nu470 to absorb blue light, or bis-acylphosphine oxide (BAPO) to absorb violet light. The 3D printer was equipped with a modular LED light that can be switched between these colors. The opaquing agent helps to confine curing to the irradiated areas, which improves the resolution.

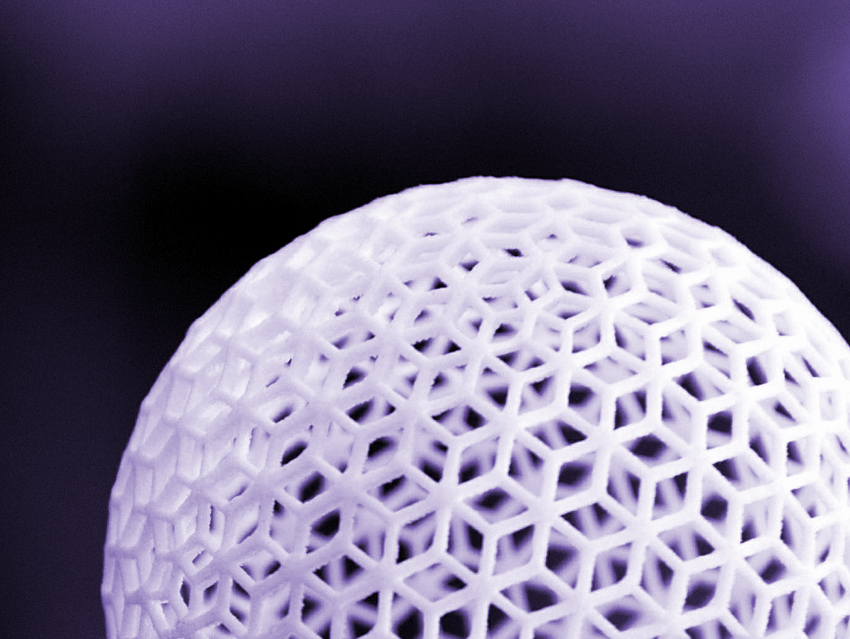

The optimized mix of components allowed the researchers to print objects with features smaller than 100 μm. They achieved fast build speeds of 33–45 mm/h. This is still slower than printing with UV light, but according to the researchers, the speed could be further improved by increasing the light intensity.

- Rapid High-Resolution Visible Light 3D Printing,

Dowon Ahn, Lynn M. Stevens, Kevin Zhou, Zachariah A. Page,

ACS Cent. Sci. 2020.

https://doi.org/10.1021/acscentsci.0c00929