Zeolites are porous aluminosilicates. They have applications, e.g., in ion-exchange processes, adsorption, and catalysis. Zeolites are very stable compared to many other porous materials. However, they are often used under very harsh conditions, for example, as a catalyst for steam cracking or exhaust gas treatment. In these processes, the zeolites are exposed to high-temperature steam, which causes degradation. This degradation generally starts at defect sites in the zeolite structure.

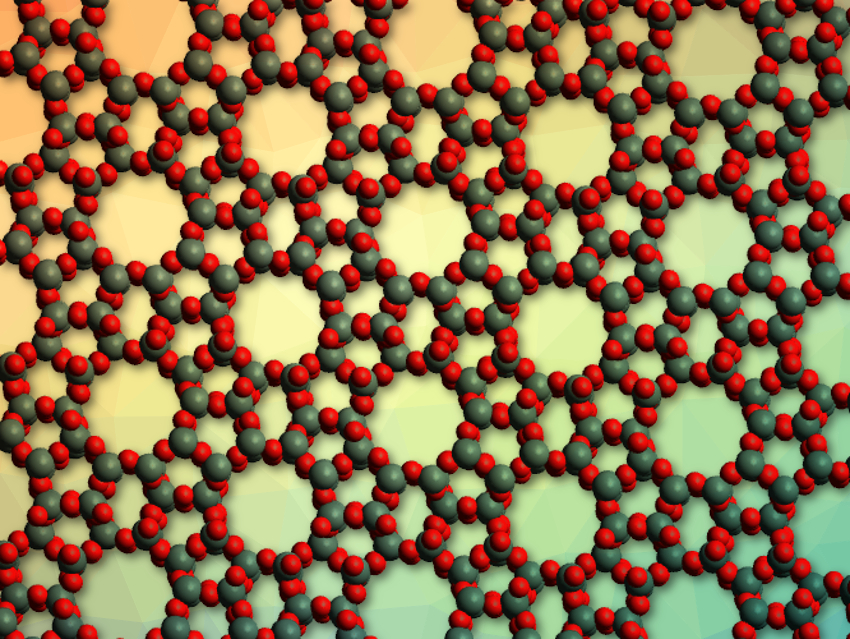

Toru Wakihara, The University of Tokyo, Japan, and colleagues have developed a method for healing defects in zeolites and making these porous materials even more stable. The team used high-silica zeolites of the types ZSM-5 (pictured), beta zeolite, and mordenite and treated them in an aqueous solution of NH4F and tetramethylammonium hydroxide (TEAOH) at 40–170 °C for 3–24 h. The samples were then washed, dried, and calcined at 550 °C.

The team found that the treated zeolites can withstand extremely high-temperature steam (900–1150 °C), while their untreated counterparts degrade under the same conditions. The team attributes this improvement to a reduction in structural defects, which is caused by silicate species that migrate within the structure and heal the defects. This migration process is promoted by the hydroxide and fluoride ions in the treatment solution, while the trimethylammonium cations act as “pore fillers” and stabilize the crystalline network during treatment.

- Extremely Stable Zeolites Developed via Designed Liquid-Mediated Treatment,

Kenta Iyoki, Kakeru Kikumasa, Takako Onishi, Yasuo Yonezawa, Anand Chokkalingam, Yutaka Yanaba, Taiji Matsumoto, Ryota Osuga, Shanmugam P. Elangovan, Junko N. Kondo, Akira Endo, Tatsuya Okubo, Toru Wakihara,

J. Am. Chem. Soc. 2020.

https://doi.org/10.1021/jacs.9b12709