Hydrogels are crosslinked hydrophilic polymers which can hold large amounts of water. They have a variety of applications, e.g., in medicine. They can also be used as coatings to combine the properties of, for example, a mechanically strong substrate with the hydrogel’s hydrophilicity and biocompatibility.

However, applying hydrogel coatings can be challenging outside of the lab. This is because the polymerization of the monomers, the crosslinking to form a polymer network, and the interlinking with the substrate usually happen in one step. Many hydrogels are made by free‐radical polymerization, which involves toxic monomers, toxic initiators, and an oxygen‐free environment.

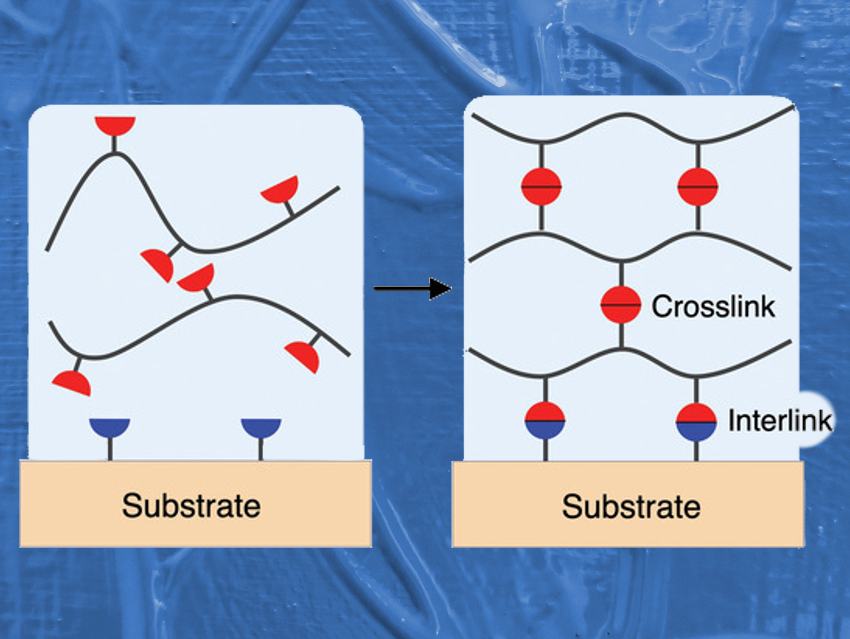

Zhigang Suo, Harvard University, MA, USA, and colleagues have developed a principle for the creation of hydrogel paints that can be used by anyone. The approach is based on the decoupling of the polymerization from crosslinking and interlinking (pictured). As an example, the monomer acrylamide and the coupling agent (3‐(trimethoxysilyl)propyl methacrylate) (TMSPMA), both dissolved in water, were copolymerized. The resulting uncrosslinked polymer was then painted onto the surface of a substrate modified with hydroxyl groups. The paint was then cured by heating it to 65 °C. During curing, it forms siloxane bonds that crosslink the polymer chains and interlink the polymer to the substrate.

In this approach, the polymerization, which involves toxic reagents, is performed before the paint or coating reaches the end-user. The hydrogel paint can be dried, ground into powders, and stored for a long time. After redissolving in water, the powder becomes hydrogel paint again. As a proof-of-concept, the team used the process to coat medical guidewires with a hydrogel and successfully reduced their friction.

- Hydrogel Paint,

Xi Yao, Junjie Liu, Canhui Yang, Xuxu Yang, Jichang Wei, Yin Xia, Xiaoyan Gong, Zhigang Suo,

Adv. Mater. 2019.

https://doi.org/10.1002/adma.201903062

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)