Magnetic microrobots could be useful, e.g., for minimally invasive surgery, drug delivery, biopsies, and diagnostics. Two of the key properties that any microrobot needs to have before it can be used in a clinical trial are the ability to efficiently respond to an applied magnetic field and a high biocompatibility.

Sangwon Kim, Salvador Pané, ETH Zurich, Switzerland, Bradley J. Nelson, ETH Zurich, Daegu Gyeongbuk Institute of Science and Technology (DGIST), and DGIST‐ETH Microrobotics Research Center (DEMRC), both Daegu, South Korea, and colleagues have created magnetic 3D microrobots from iron. The researchers made the microrobots using a template-assisted electrodeposition method in 3D-printed micromolds. The electrolyte for the deposition process was an aqueous solution of FeSO4⋅7H2O, FeCl2⋅4H2O, and NH4Cl. The micromolds were fabricated from a photoresist (light-sensitive material) using a laser with a 780 nm wavelength.

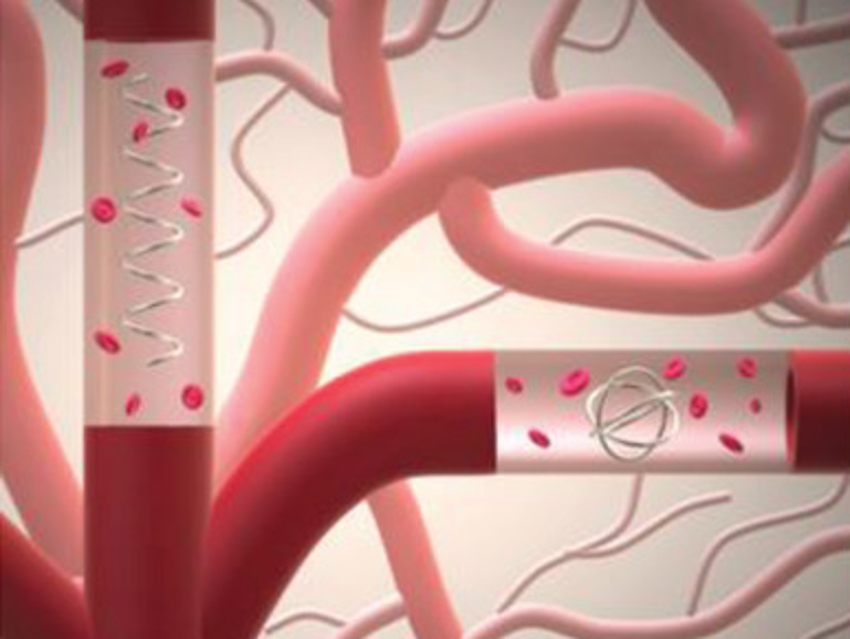

The team fabricated iron-based microrollers (pictured right) and microswimmers (pictured left) which can achieve a motion speed of 20 body lengths per second. The microrobots can also perform 3D motions in viscous environments and can overcome higher flow viscosities compared to other 3D microswimmers. The microrobots were also found to have a good biocompatibility.

- 3D Fabrication of Fully Iron Magnetic Microrobots,

Carlos C. J. Alcântara, Sangwon Kim, Sunkey Lee, Bumjin Jang, Prakash Thakolkaran, Jin-Young Kim, Hongsoo Choi, Bradley J. Nelson, Salvador Pané,

Small 2019.

https://doi.org/10.1002/smll.201805006