BASF Venture Capital GmbH is investing in Prismlab, a Chinese provider of 3D printing processes and 3D printers. This is BASF’s first direct investment in a Chinese company.

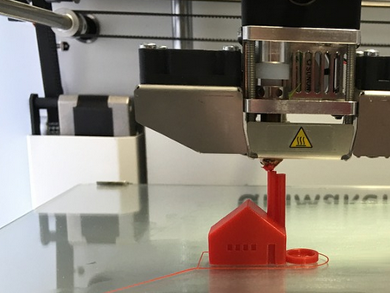

Prismlab has developed a patented 3D printing process that is characterized by a very high printing speed, high level of precision and lower printing costs. The venture investment will allow Prismlab to further advance its product development while strengthening its market reach to the global market.

Prismlab’s “Pixel Resolution Enhanced Technology” is based on stereolithography (SLA). SLA allows comparatively large components to be produced using light-curing resins. The technology increases the printing resolution without compromising printing speed. To increase the amount of energy brought into a pixel, each pixel in the resin is divided into several small sections, which can be cured individually by exposure to LCD light. This makes the energy input into each pixel significantly higher than similar processes that expose each pixel to light once. This allows comparatively large and stable components or numerous parts to be printed in the same production step. With the use of LCD light, it also reduces process costs. This advantage opens opportunities in the footwear and furniture industry. And it allows large and stable components, such as medical braces and anatomical models, to be 3D printed for the first time.

Along with this patented process, Prismlab also markets 3D printers and other related services.