The oceans contain billions of tons of uranium, much more than ores on land. This makes the capture of uranium from seawater a potential way to support nuclear power production. The use of fiber‐based adsorbents is a promising cost-effective and environmentally friendly method for this.

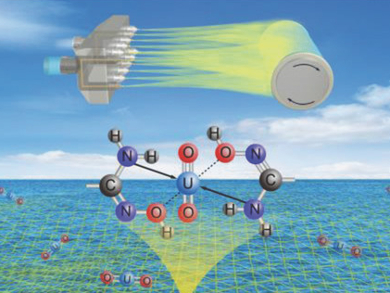

Ning Wang, Hainan University, Haikou, China, Xiaolin Wang, China Academy of Engineering Physics, Mianyang, Hui Wu, Tsinghua University, Beijing, China, and colleagues have developed a method for the large-scale production of high-performance poly(imide dioxime) nanofiber (PIDO NF) adsorbents for uranium extraction from seawater. The team modified polyacrylonitrile (PAN) using hydroxylamine to give a PIDO solution. This PIDO solution was then turned into nanofibers using a blow spinning strategy (pictured top). The spinning process can use multiple nozzles at once, which allows for easy scale-up.

The resulting nanofibers are porous, flexible, and mechanically strong. The functional groups on their surface bind uranium efficiently (pictured bottom). The PIDO NFs have a significantly improved uranium extraction performance compared with previously available fiber‐based adsorbents. The maximum adsorption capacity reached 951 mg U/g in uranium-spiked seawater. The average amount of uranium uptake from non‐spiked natural seawater was 8.74 mg U/g. Up to 98.5 % of the adsorbed uranium could be recovered from the material using a sodium carbonate/hydrogen peroxide solution. Thus, the adsorbents can be regenerated and reused.

- Significantly Enhanced Uranium Extraction from Seawater with Mass Produced Fully Amidoximated Nanofiber Adsorbent,

Dong Wang, Jianan Song, Jun Wen, Yihui Yuan, Zhenglian Liu, Sen Lin, Haiyang Wang, Haolun Wang, Shilei Zhao, Xuemei Zhao, Minghao Fang, Ming Lei, Bo Li, Ning Wang, Xiaolin Wang, Hui Wu,

Adv. Energy Mater. 2018.

https://doi.org/10.1002/aenm.201802607