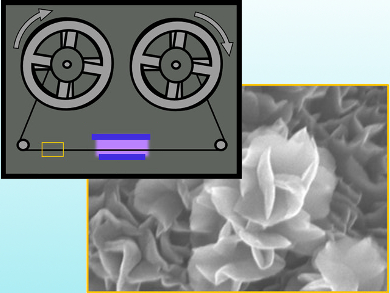

Graphitic petals (pictured bottom right) are used throughout the engineering sector as an additive to enhance the performance of various materials. Despite their useful properties, their production has been limited to batch processes. To fully realize their potential, a continuous manufacturing process would be useful.

Timothy S. Fisher, University of California, Los Angeles (UCLA), USA, and colleagues have created a roll-to-roll chemical vapor deposition (R2R-CVD) method. The tools to deposit the carbon atoms were custom built by the researchers. In an inert process chamber (pictured top left), the graphitic petals were formed from a gas mixture (Ar, H2, CH4, N2, O2) in a radio-frequency-induced plasma (pictured violet) and deposited onto a moving carbon fiber substrate.

The researchers characterized the graphitic petals using cold field emission scanning electron microscopy (FE‐SEM), Raman spectroscopy, as well as electric resistance and capacitance measurements. The team tested if the graphitic petals could be used for supercapacitor applications. The results showed individual capacitance values for the graphitic particles of 0.135–0.170 Fm–1, with a weight-specific capacitance of 0.41–5.17 Fg–1 and a volumetric specific capacitance of 0.734–9.26 Fm–3. The graphitic petals had a minimum electrical resistance of 80 Ohm m–1. According to the researchers, the resulting material is suitable for increasing the capacity of supercapacitors, strengthening composite materials, and increasing the sensitivity of electrochemical sensors.

- Roll-to-Roll Production of Graphitic Petals on Carbon Fiber Tow,

Kimberly R. Saviers, Majed A. Alrefae, Timothy S. Fisher,

Adv. Eng. Mater. 2018.

https://doi.org/10.1002/adem.201800004