Rechargeable lithium ion batteries (LIBs) are widely used for applications ranging from portable electronics to electric vehicles. However, commercial LIBs are mostly limited to simple shapes and consist of thin electrodes, which limit their energy capacities. To meet the increasing demand for LIBs with higher capacities, faster charge rates, and lower costs, new battery materials and fabrication methods are required.

Jennifer A. Lewis, Harvard University, Cambridge, MA, USA, and colleagues have fabricated fully 3D-printed LIBs composed of thick electrodes that exhibit high areal capacity, while largely retaining the areal power density of thin electrodes. The LIBs are printed from a biphasic electrode ink containing both the active electrode particles, LiFePO4 (LFP, cathode) and Li4Ti5O12 (anode), as well as conductive Ketjenblack carbon particles to overcome the resistive nature of most electrochemically active Li-ion compounds. Additionally, the researchers developed packaging and separator inks made of ceramic-filled polymer composites that can be UV-cured upon printing.

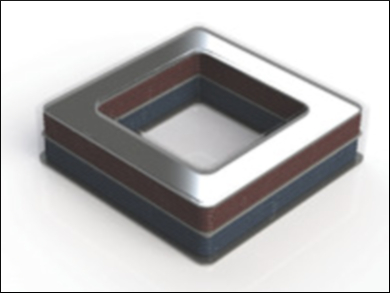

The 3D-printed LIBs were encased between two laser-cut glassy carbon current collectors to give packaged LIBs with 1 mm- thick electrodes in a customized design. The batteries had areal capacities of 4.45 mAh cm–2 at 0.14 mA cm–2, which shows their promise for future applications where batteries may be directly printed and integrated into devices.

- 3D Printing of Customized Li-Ion Batteries with Thick Electrodes,

Teng-Sing Wei, Bok Yeop Ahn, Julia Grotto, Jennifer A. Lewis,

Adv. Mater. 2018.

https://doi.org/10.1002/adma.201703027