Electrospinning is a method to produce fibers from polymers. The process uses a voltage difference to draw the polymer fibers from a nozzle. Nanofiber mats produced by electrospinning have useful properties such as high surface areas and high porosity. However, the mats’ often poor mechanical properties hinder their large-scale application.

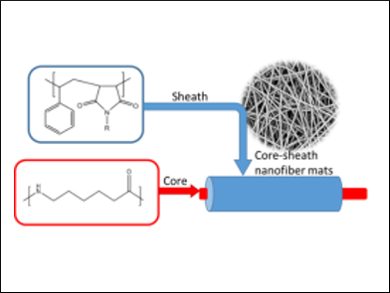

Nonjabulo Prudence Gule, Stellenbosch University, South Africa, and colleagues have developed antimicrobial core-sheath nanofibrous mats with improved mechanical properties. The team used coaxial electrospinning to create fibers with a mechanically strong nylon 6 polymer core and a sheath made from the antimicrobial polymer poly(styrene-co–N-(N‘,N‘-dimethyl-3-aminopropyl)maleimide).

The researchers found that the resulting mats have improved mechanical strength, which allows them to be used, e.g., in filtration experiments. The nanofibers also retained the antimicrobial properties of the sheath material. The mats were effective against both Gram-positive Staphylococcus aureus and Gram-negative Pseudomonas aeruginosa.

- Novel core-sheath antimicrobial nanofibrous mats,

Renier Kemp, Bert Klumperman, Nonjabulo Prudence Gule,

J. Appl. Polym. Sci. 2018.

https://doi.org/10.1002/app.46303