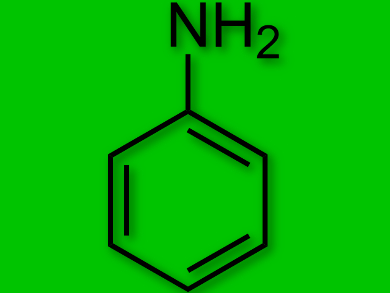

Covestro has obtained aniline from biomass in a lab scale process. Until now, only fossil raw materials had been used for the production of aniline, which plays an important role in the chemical industry and is used as starting material for many products. Covestro’s process uses a microorganism as a catalyst to first convert industrial sugar into an aniline precursor. This is converted to aniline using chemical catalysis in a second step.

The company plans to further develop the process together with the University of Stuttgart, the CAT Catalytic Center at RWTH Aachen University, and Bayer AG, Ludwigshafen, all Germany. The first step is to upscale the process in a pilot plant. The long-term research project will receive funding for a period of two and a half years through the FNR (Fachagentur Nachwachsende Rohstoffe e.V.), a project agency of Germany’s Federal Ministry of Food and Agriculture (funding code: 22010215).

About five million metric tons of aniline are produced annually worldwide. Covestro is among the leading producers with a production capacity of about one million metric tons. The company uses aniline as a precursor for rigid polyurethane foam, a highly efficient insulating material used in buildings and refrigeration systems.

- Covestro AG, Leverkusen, Germany