Flexible solid-state supercapacitors (SCs) are promising materials for lightweight energy storage in wearable electronics. These devices are typically made by stacking several components into complex multilayer architectures, which can suffer from poor mechanical integrity.

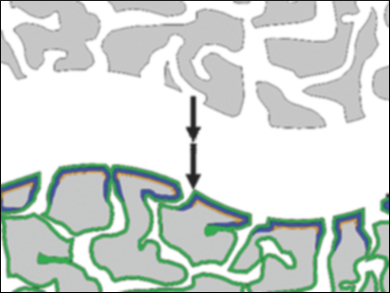

Karen Gleason, Massachusetts Institute of Technology (MIT), Cambridge, USA, and colleagues have developed a straightforward route to solid-state SCs that circumvents the complicated stacking of individual components. The researchers first sputter-coated a thin layer of gold onto both sides of a nylon membrane, followed by chemical vapor deposition (CVD) of poly(3,4-ethylenedioxythiophene) (PEDOT) as the pseudocapacitive layer. Due to the limited penetration depth of the CVD process, the unmodified interior of the paper substrate remained to serve as the separator. The porous sheet was then impregnated with the precursors for an ion gel electrolyte. After thermally initiated polymerization, an integrated single-sheet SC was obtained.

The resulting SCs showed high volumetric capacitance (11.3 F cm–3), energy density (2.98 mWh cm–3), and power density (0.42 W cm–3). The researchers point out that such vapor-based printing methods could allow the combination of energy storage and energy harvesting devices on a single substrate, thereby paving the way to self-powered systems.

- Monolithic Flexible Supercapacitors Integrated into Single Sheets of Paper and Membrane via Vapor Printing,

Andong Liu, Peter Kovacik, Nolan Peard, Wenda Tian, Hilal Goktas, Jonathan Lau, Bruce Dunn, Karen K. Gleason,

Adv. Mater. 2017.

DOI: 10.1002/adma.201606091

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)