Flexible conductive materials are often realized through the deposition of thin metal films on stretchable and flexible substrates. A downside of this approach is the formation of cracks or even delamination of the film after a high number of deformations. The use of nontoxic liquid metals infiltrated in porous substrates is therefore an interesting alternative.

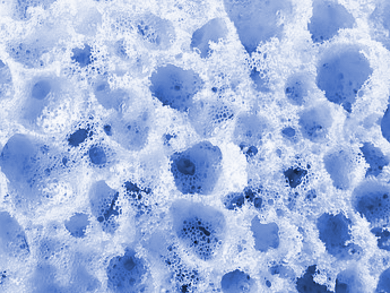

Xuechang Zhou, Shenzhen University, China, and colleagues have developed a simple method to make all-soft liquid metal sponges with high electrical conductivity and flexibility. First, a porous poly(dimethysiloxane) (PDMS) sponge was prepared by infiltrating the respective silicone precursor into a sugar cube, which was dissolved in hot water after polymerization. Subsequently, GaInSn was incorporated in the PDMS sponge by placing the samples in the liquid metal. By varying the amount of metal in the pores, the conductivity could be adjusted, reaching values comparable to that of bulk GaInSn.

The conductivity remained constant when the samples were stretched and did not deteriorate significantly after 10.000 stretching cycles. The researchers envision their low-cost and simple process to be directly applicable to the development of wearable and flexible electronics.

- Liquid metal sponges for mechanically durable, all-soft, electrical conductors,

Suqing Liang, Yaoyao Li, Yuzhen Chen, Jinbin Yang, Taipeng Zhu, Deyong Zhu, Chuanxin He, Yizhen Liu, Stephan Handschuh-Wang, Xuechang Zhou,

J. Mater. Chem. C 2017.

DOI: 10.1039/c6tc05358k

My name is Willie and I’m interested in finding a cloth like material that can carry a low currant. A tens pad is perfect except it’s sticky.

[email protected] thanks