The miniaturization of soft materials is a promising route to new devices in fields such as healthcare or bioengineering. While microprinting via two-photon crosslinking (TPC) is already able to create complex 3D structures with sub-micrometer precision, these materials typically lack chemical functionality, leaving them rather passive systems.

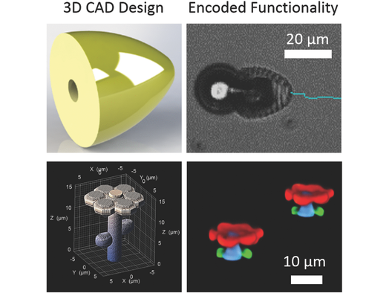

Metin Sitti, May Planck Institute for Intelligent Systems, Stuttgart, Germany, and co-workers have developed a two-step process that uses TPC to make hydrogel-based micromaterials with intricate structures and functionalities. In the first step, the 3D design is realized by crosslinking poly (ethylene glycol) diacrylate. Unreacted polymer precursor is then removed and a new precursor bearing the desired functionality is introduced. These functionalities are linked to the 3D design at specific sites by selective illumination of the sample during the second TPC step.

As a proof of concept, the team first prepared a bullet-shaped microswimmer, in which the inner cavity was selectively modified with Pt NPs over several steps. To further underline the importance of this method for biomaterials development, the researchers designed a microflower bearing orthogonal biotin, thiol, and alkyne groups at precisely defined positions.

- 3D Chemical Patterning of Micromaterials for Encoded Functionality,

Hakan Ceylan, Immihan Ceren Yasa, Metin Sitti,

Adv. Mater. 2016.

DOI: 10.1002/adma.201605072