Wearable electronic devices require materials that are flexible and lightweight. This is especially challenging for the devices’ energy sources. Triboelectric nanogenerators (TENGs) are one approach to solving this problem. They can convert mechanical movement into an electrostatic energy potential between two materials. The need for packing two materials in close contact can make miniaturization of such devices difficult, however.

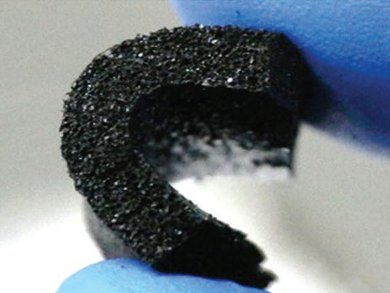

Zhong Lin Wang, Guang Zhu, Beijing Institute of Nanoenergy and Nanosystems, China, and colleagues have developed a stretchable porous nanocomposite that combines two materials in one spongelike structure, where each cavity in the “sponge” serves as a TENG unit. The team used sodium chloride powder as a sacrificial template, which they combined with multiwalled carbon nanotubes (CNTs) and uncured polydimethylsiloxane (PDMS). After curing the PDMS polymer, the sodium chloride was dissolved in water, leaving cavities that create the desired porous structure (pictured).

When the elastic material is subjected to mechanical stress, such as compression, bending, or twisting, the deformation causes contact electrification between the carbon nanotubes and the polymer matrix, and electrons flow through the network of CNTs. The team tested the material inside a shoe’s insole, and it generated enough electricity during walking to power commercial light-emitting diodes (LEDs).

- Stretchable Porous Carbon Nanotube-Elastomer Hybrid Nanocomposite for Harvesting Mechanical Energy,

You Jun Fan, Xian Song Meng, Hua Yang Li, Shuang Yang Kuang, Lei Zhang, Ying Wu, Zhong Lin Wang, Guang Zhu

Adv. Mater. 2016.

DOI: 10.1002/adma.201603115