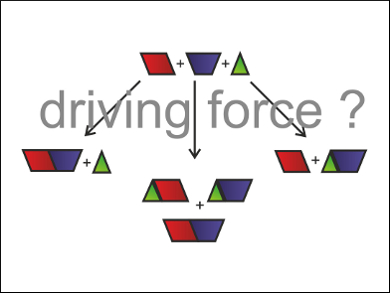

Co-crystallization by grinding an active pharmaceutical ingredient (API) with a coformer can improve physicochemical properties such as the stability against physical or chemical stress. One example is grinding in a ball mill, which uses little to no solvents and gives access to many co-crystals that cannot be synthesized under common synthesis conditions. However, fundamental understanding of the formation pathways and driving forces during milling is still lacking and reliable prediction of the co-crystallization products is impossible.

Franziska Emmerling, BAM Federal Institute for Materials Research and Testing, Berlin, Germany, and colleagues chose a set of multi-component milling reactions based on four co-crystals, including the coformer anthranilic acid and the APIs carbamazepine, salicylic acid, theobromine, and theophylline, to address the different aspects of milling reactions. All grinding experiments were conducted in a MM400 mixing mill at a frequency of 30 Hz.

The results indicate that the co-crystal milling product is not only related to the preferred intermolecular interaction. The kinetic aspects also have to be considered, making these mechanochemical co-crystallization reactions more complex than generally expected.

- Survival of the Fittest: Competitive Co-crystal Reactions in the Ball Mill,

Franziska Fischer, Maike Joester, Klaus Rademann, Franziska Emmerling,

Chem. Eur. J. 2015.

DOI: 10.1002/chem.201500925