Hydrogen Release from Liquid Storage Media

Hydrogen is considered to be the energy source of the future: the first vehicles powered by hydrogen fuel cells are already on the market. However, the problem of hydrogen storage has not been solved in a satisfactory way. American scientists have now developed catalytically active micromotors that significantly increase the release of hydrogen from liquid storage media. In the journal Angewandte Chemie, they introduce their new concept with a model vehicle powered by a hydrogen–oxygen fuel cell.

Solutions of hydrogen-containing salts like sodium borohydride (NaBH4) offer many advantages as hydrogen storage media. Most importantly, the hydrogen they release is very pure, which is an important requirement for the smooth operation of fuel cells. To date, most catalysts used for releasing hydrogen from NaBH4 have been either thin films embedded in support materials or nanoparticles. The speed and efficiency of hydrogen release in these systems is limited by deactivation of the surfaces through deposition of the reaction byproduct (NaBO2), blockage by hydrogen bubbles, and concentration gradients of the NaBH4 in solution.

Janus-Faced Microparticles as Moving Catalysts

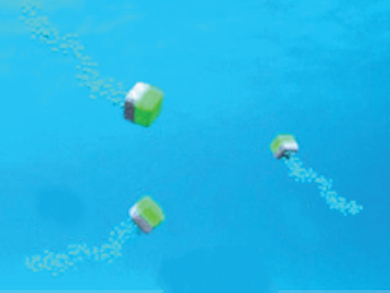

A team headed by Joseph Wang at the University of California, San Diego, La Jolla, USA, has now solved these major problems. The key to their success is a catalyst in the form of self-propelled “micromotors”. These consist of particles known as Janus microparticles, named after the Roman god Janus. Like the god, these tiny particles have two different “faces”: one side is made of platinum black, a very fine, catalytically active platinum powder and the other half is coated with titanium, which makes it inactive and allows for directional motion. When these micromotors are placed in a solution of NaBH4, hydrogen is only released on the platinum side. The storage medium thus also acts as the “fuel” for the micromotors, which are propelled by the resulting gas bubbles. This causes the liquid to be mixed very thoroughly, avoiding local drops in concentration. In addition, neither the gas bubbles nor the solid byproduct can stick to the catalytic surface. This results in significantly faster release of hydrogen than with conventional static catalysts.

To demonstrate their concept, the scientists equipped a small model car with a hydrogen–oxygen fuel cell. The hydrogen was released on board from a NaBH4 solution, as described above. The necessary oxygen was also produced on board by an analogous system: catalytic splitting of dissolved hydrogen peroxide (H2O2) with the same type of platinum/titanium micromotors.

The advantage of this type of system is that liquid fuels are used, so no storage of gases is required. The required gases are very rapidly released on demand and brought directly to the fuel cell electrodes.

- Micromotor-Based Energy Generation,

Virendra V. Singh, Fernando Soto, Kevin Kaufmann, Joseph Wang,

Angew. Chem. Int. Ed. 2015.

DOI: 10.1002/anie.201501971