A recent breakthrough in developing high-efficiency solar cells was made by replacing the light-harvesting dye with organometal halide perovskites. A triiodide perovskite (CH3NH3PbI3)-based solar cell with an expensive organic spiro-MeOTAD (a spirobifluorene) as the hole-transporting material was demonstrated to be very promising, with efficiencies of more than 15.0 % [1,2]. However, CH3NH3PbI3 decomposes on exposure to moisture in the air. To develop air-stable perovskite materials, mixed halide perovskites CH3NH3PbI3−yXy (X = Cl and Br) are being studied.

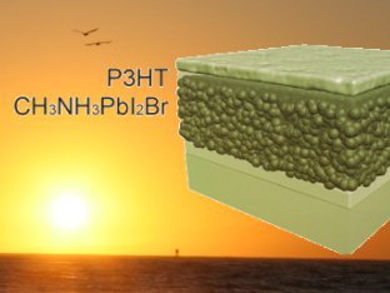

Lianzhou Wang, University of Queensland, Australia, and co-workers have successfully fabricated stable and low-cost all-solid-state mesoscopic perovskite solar cells using stable CH3NH3PbI2Br as a light absorber and poly(3-hexylthiophene) (P3HT) as a hole-transporting layer. The optimized device achieved a power conversion efficiency of 6.64 %. The incorporation of bromine led to an impressively longer charge carrier lifetime compared to triiodine perovskite. The solar cells also retained their photovoltaic performance well when they were exposed to air without any encapsulation.

Use of a low-cost thin P3HT layer as a hole-transporting material rather than spiro-MeOTAD will remarkably reduce the fabrication cost of the whole device. Thus, the combination of CH3NH3PbI2Br and P3HT may render a practical, stable, and cost-effective solid-state photovoltaic system.

- Stable and Low-Cost Mesoscopic CH3NH3PbI2Br Perovskite Solar Cells by using a Thin Poly(3-hexylthiophene) Layer as a Hole Transporter,

Meng Zhang, Miaoqiang Lyu, Hua Yu, Jung-Ho Yun, Qiong Wang, Lianzhou Wang,

Chem. Eur. J. 2014.

DOI: 10.1002/chem.201404427

[1] H. S. Kim, C. R. Lee, J. H. Im, K. B. Lee, T. Moehl, A. Marchioro, S. J. Moon, R. Humphry-Baker, J. H. Yum, J. E. Moser, M. Gratzel, N. G. Park, Sci. Rep. 2012, 2, 591. DOI: 10.1038/srep00591

[2] J. Burschka, N. Pellet, S. J. Moon, R. Humphry-Baker, P. Gao, M. K. Nazeeruddin, M. Gratzel, Nature 2013, 499, 316–319. DOI: 10.1038/nature12340

I hope this message finds you well. I am currently working on fabricating FACsPbIBr perovskites using the spin-coating technique. However, I would greatly appreciate your guidance on the growth procedures, specifically for the one-step and two-step methods.

One-Step Growth:

Would it be better to prepare a single solution containing all precursors (FAI, CsI, PbBr₂) from the start, or are there specific adjustments or conditions you recommend to optimize this method?

Two-Step Growth:

How is this typically done? Should I start by depositing a layer of PbI₂ (or PbBr₂) and then add the other precursors in a second step? If so, what conditions (e.g., spin-coating speeds, antisolvent use, or annealing) would you suggest for each step to achieve high-quality layers?

Your expertise and advice on these questions would be invaluable for improving my experimental protoco