Wonder Material

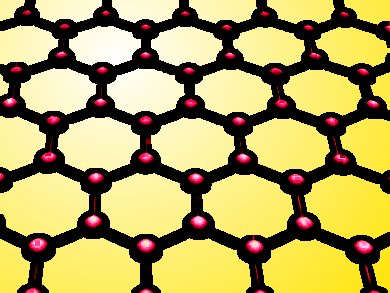

It is perhaps unnecessary to remark on how excited many materials scientists, chemists, engineers, and futurologists are about the possibilities for novel technology that might emerge from the discovery of graphene – the “monolayer form” of the carbon allotrope graphite. Suffice to say, however, that it is repeatedly described as a record-breaking, superstrong wonder material with physical, chemical and optoelectronic properties that may well lead to the next generation of adaptable structural composites, energy-converting catalytic membranes, and much more.

Moreover, it is hailed repeatedly as the natural successor for silicon in the computer age. The graphene story will unfold in the coming decades and we will learn of its promise fulfilled as the devices and gadgets founded on laboratory science emerge from industrial startups and fabrication plants. Before then, however, there is the small problem of making this material efficiently and effectively in a form that is amenable to further processing.

Back in 1947, the properties of a hypothetical form of graphite just one atom thick and resembling the pattern of chicken-wire fencing was discussed by theoretical physicist Philip Russell Wallace. Chemist Hanns-Peter Boehm and colleagues were first to isolate, identify and define graphene in 1961. Although, weirdly, the 2010 Nobel Prize went to two physicists at Manchester University, UK, Andre Geim and Konstantin Novoselov, for their working on graphene their having peeled off the material from graphite with sticky tape.

Today, epitaxial growth by chemical vapor deposition (CVD) is considered the most likely candidate for mass production of graphene, involving, as it does, deposition of an ordered layer of carbon atoms from the vapor phase on to a suitable substrate. At least it was, until German scientists put their finger on a novel idea …

Graphene Synthesis

Frank Müller, Samuel Grandthyll, and Karin Jacobs of Saarland University, Saarbrücken, Germany, and Stefan Gsell, Michael Weinl, and Matthias Schreck of the University of Augsburg, Germany, cite a study by Ruan et al. [1] in which it was proved that for CVD almost anything can act as an organic carbon source – sugar, cookie crumbs, even chocolate. The process of molecular beam epitaxy would release the carbon atoms from these unusual starting materials. However, CVD is an expensive and unwieldy technique. Liquids rather than vapors are so much easier to handle and they can deposit on to metal surfaces a prerequisite for many of the plans for graphene.

The German team has now discovered that rather than depositing carbon from the vapor phase, epitaxial growth of a graphene monolayer is also possible using a human fingerprint as a liquid precursor. One might imagine that such a heterogeneous mixture of oils, water, proteins, salts and other substances might not offer a sufficiently uniform precursor.

Nevertheless, strange as it may seem, the researchers have now demonstrated that liquid precursor deposition (LPD) from fingerprints, a heterogeneous liquid, makes well ordered graphene layers on transition metal surfaces.

Their tests demonstrate that the purity and homogeneity of the resulting graphene layer is as high using a fingerprint as is possible with ultrapure single-compound synthetic precursors including acetone and acetaldehyde.

Müller and colleagues suggest that almost everything we need to know about the physical and chemical properties of graphene have now been ascertained and as the journal Nature reported [2], we are now at the quest stage, especially given a massive push from the European Commission graphene flagship, Gothenburg, Sweden, to develop graphene syntheses and applications.

“Nobody would seriously consider the application of this synthesis route in a technological production step”, the team admits. “However, the current experiments prove the reliability of LPD synthesis because graphene growth from fingerprints, although starting with a highly uncontrolled way to deposit carbon, achieves the same results as the LPD synthesis route using pure synthetic precursors.”

Applications?

Despite the simplistic myth of the Nobel version of the graphene story, the epitaxial growth of this material is literally 50 years old, as mentioned above. There have in fact been hundreds of papers specifically devoted to it, graphene expert Walt de Heer reminds us. He heads the Epitaxial Graphene Laboratory at the Georgia Institute of Technology, Atlanta, GA, USA.

“As for the fingerprint as precursor, I recently saw an invited talk at the MRS, where a guy from Sony actually produced graphene directly on copper with no carbon precursors at all”, he told ChemistryViews.org. “The source was apparently, carbon dissolved in the copper itself.” He adds that he believes, “that the entire effort to produce ever cheaper graphene is misguided. Graphene is a wonder material still looking for a single wonderful application. The material with a lot of promise, and it seems to stay that way.”

- Graphene from Fingerprints: Exhausting the Performance of Liquid Precursor Deposition,

Frank Müller, Samuel Grandthyll, Stefan Gsell, Michael Weinl, Matthias Schreck, Karin Jacobs,

Langmuir 2014.

DOI: 10.1021/la500633n

[1] Growth of Graphene from Food, Insects, and Waste, Gedeng Ruan, Zhengzong Sun, Zhiwei Peng, James M. Tour, ACS Nano 2011, 5 (9), 7601–7607. DOI: 10.1021/nn202625c

[2] Mark Peplow, Graphene: The quest for supercarbon, Nature 2013, 503, 327–329. DOI: 10.1038/503327a