Tin-based oxide materials have attracted considerable attention as potential materials for use in lithium-ion batteries due to a significant advantage of high specific capacity.

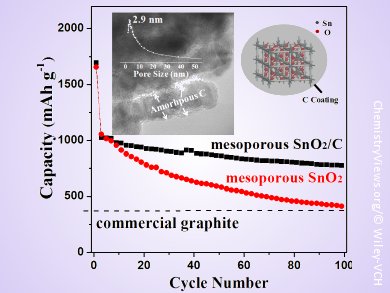

By using a facile vacuum-assisted impregnation method, Guoxiu Wang, University of Technology Sydney, Australia, Shi Zhang Qiao, The University of Adelaide, Australia, and their groups have prepared ordered mesoporous SnO2/C composites consisting of an SnO2 crystalline core and amorphous carbon shell with mesoporous silica (SBA15) as a template and an organic tin salt (C4H9SnCl3) as a tin source—an elegant method in comparison to other analogues.

With respect to their potential use as anode materials in lithium-ion batteries, the high surface area, large pore volume, and narrow pore-size distribution of these SnO2/C composites lead to improved lithium-ion intercalation and electrolyte diffusion and the carbon shell leads to a low resistance and high charge transfer dynamics. The discharge capacity is more than double that of the theoretical capacity of commercial graphite material. The capacity at a discharge current of 10 A g–1 is 510 mAhg–1, illustrating the promising potential of this mesoporous SnO2/C as a high-power source for next-generation electric vehicles.

- Ordered Mesoporous Core/Shell SnO2/C Nanocomposite as High-Capacity Anode Material for Lithium-Ion Batteries,

H. Liu, S. Chen, G. Wang, S. Z. Qiao,

Chem. Eur. J. 2013.

DOI: 10.1002/chem.201303400