Shilun Qiu and colleagues, Jilin University, China, report a convenient and universal method to prepare free-standing metal-organic framework (MOF) membranes with manifold size and shape and a thickness from hundreds of nanometers to hundreds micrometer.

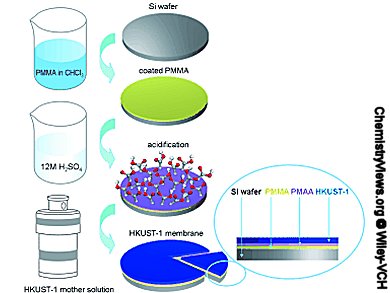

First, a poly(methyl methacrylate) (PMMA) membrane was spin coated on a template substrate, which could be any solid surface of, for example, metal or plastics. Then the PMMA surface was hydrolyzed by concentrated sulfuric acid and converted into poly(methacrylic acid) (PMAA). Next, the PMMA–PMAA-coated substrate was immersed into a MOF precursor solution in autoclaves for a suitable reaction time. For the further preparation of a free-standing MOF membrane, the as-synthesized MOF membrane can be separated from the substrate by dissolving the PMMA–PMAA in chloroform.

By using this method (pictured), a stainless steel net/PMMA–PMAA-supported HKUST-1 membrane was fabricated and applied in gas separation. Results indicated that such a membrane has a high separation factor to H2/N2, H2/CH4, H2/CO2 gas mixtures

This membrane fabrication method is simple and convenient. It can be readily applied to a variety of other material compositions to produce functional membranes with diverse micropore structures, thus opening up a host of opportunities for the development of new functional nanodevices.

- Polymer-Supported and Free-Standing Metal–Organic Framework Membrane,

Teng Ben, Chunjing Lu, Cuiying Pei, Shixian Xu, Shilun Qiu,

Chem. Eur. J. 2012, 16, 10250–10253.

DOI: 10.1002/chem.201201574 - Presented at the 4th EuCheMS Chemistry Congress, Prague

Chemistry—A European Journal invited various speakers of the Congress to contribute an article to their special issue of the conference.