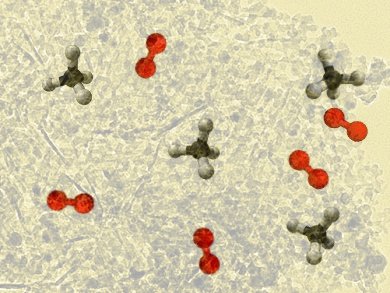

Partial oxidation of methane (POM) to CO is gaining importance as petroleum reserves dwindle. Cobalt-based catalysts are often used in this reaction, but they suffer from low activities and stabilities. Different calcination temperatures and various supports have been evaluated to overcome these disadvantages.

Chuan-Jing Huang and colleagues, Xiamen University, China, have found any easy way to improve the properties of cobalt-based catalysts for POM. After reduction of the calcined cobalt/alumina catalyst with H2 to give reactive cobalt metal, they pretreated the catalyst with feedstock gas (CH4/O2/Ar mixture) at 750 °C for 30 min. The pretreatment leads to higher methane conversion, better selectivity for CO, and better long-term stability. Characterization of the catalyst indicates that the pretreatment modifies the catalyst’s surface structure to give Co metal that is highly dispersed in an α-Al2O3 phase, which results in the improved catalyst properties.

Image: © Wiley-VCH

- Effect of Calcination Temperature and Pretreatment with Reaction Gas on Properties of Co/γ-Al2O3 Catalysts for Partial Oxidation of Methane,

N.-W. Zhang, C.-J. Huang, X.-Q. Zhu, J.-D. Xu, W.-Z. Weng, H.-L. Wan,

Chem. Asian J. 2012.

DOI: 10.1002/asia.201200180