The sesquiterpene endoperoxide artemisinin is currently the most effective treatment against multi-drug resistant Plasmodium species, which are responsible for malaria. Artemisinin combination treatments (ACTs) are now first-line drugs, as recommended by the WHO.The compound is extracted from the plant Artemisia annua (sweet wormwood), now cultivated in many countries for this purpose. However, reliance on cultivated A. annua restricts the supply of the drug and elevates costs for the patients.

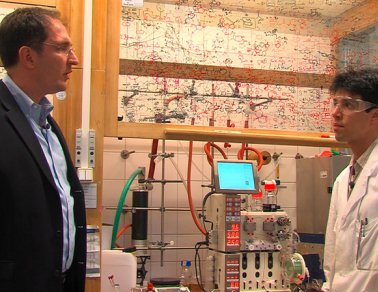

Peter H. Seeberger (left) und François Lévesque, Freie Universität Berlin and Max-Planck Institute for Colloids and Interfaces, Postdam, Germany, developed a continuous-flow conversion of dihydroartemisinic acid, derived from artemisinic acid by hydrogenation or produced by fermentation in engineered yeast, into artemisinin. Central to the reaction is a continuous photochemical transformation involving a singlet-oxygen induced ene reaction and the addition of triplet oxygen, which triggers the reaction cascade that incorporates the essential endoperoxide group.

This technically simple, efficient, and inexpensive synthesis is readily scalable by virtue of the continuous-flow process, and does not require isolation and purification of intermediates. Combined with the production of artemisinic acid in engineered yeast, access to the much needed malaria drug is now possible by semi-synthesis rather than isolation from plants.

Peter Seeberger assumes that 800 of their photoreactors would suffice to cover the global requirement for artemisinin and that the process could be ready for technical use in six months. This would alleviate the global shortage of artemisinin and greatly reduce costs.

Image: ©: Peter Seeberger

- Continuous-Flow Synthesis of the Anti-Malaria Drug Artemisinin,

F. Levesque, P. H. Seeberger,

Angew. Chem. Int. Ed. 2012, 51.

DOI: 10.1002/anie.201107446