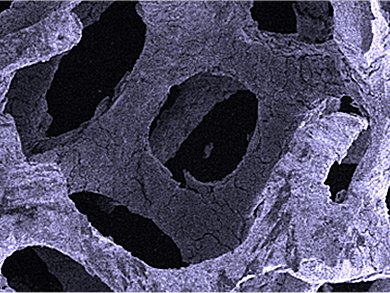

For catalytic reaction engineers, solid foams are a useful tool. Their open-pore cell structure creates a high surface area, small diffusion length, and reduces the pressure drop in the reactor. Metallic foams are advantageous over ceramic foams as they have a higher mechanical resistance, thermal conductivity, and cell density. Electrophoretic deposition (EPD) can be used to apply the catalytic coating to metallic foams. Their main disadvantage is that they require an additional pretreatment step to improve the adherence of catalytic coatings.

T. Alexander Nijhuis and colleagues, Eindhoven University of Technology, The Netherlands, demonstrate the coating of aluminum foams with highly acidic zirconium phosphate by EPD, thus avoiding the anodization pretreatment of the foam. This is a major improvement on the traditional washcoating method used to prepare this popular catalyst.

Electrical potential was applied to the aluminum foam to attract charged particles of protonated zirconium phosphate from solution. Owing to stabilization of the particles on the foam surface preventing particle agglomeration, the foam catalyst had an even higher surface than the bare aluminum foam.

The catalyst was applied to the dehydration of fructose to 5-hydroxymethyl-2-furaldehyde.

- Zirconium Phosphate Coating on Aluminum Foams by Electrophoretic Deposition for Acidic Catalysis,

V. V. Ordomsky, J. C. Schouten, J. van der Schaaf, T. A. Nijhuis

ChemCatChem 2012, 4, 129–133.

DOI: 10.1002/cctc.201100205