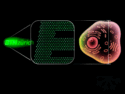

Emulsions have long been utilized to make materials for foods, drugs, cosmetics, and displays because of their efficient encapsulation properties. Multiple emulsion drops of high order — drops within drops — are useful in the production of complex microcapsules. They are used for encapsulation and sequential release of multi-component active materials while avoiding cross-contamination. Production of such multiple emulsion drops remains a challenge.

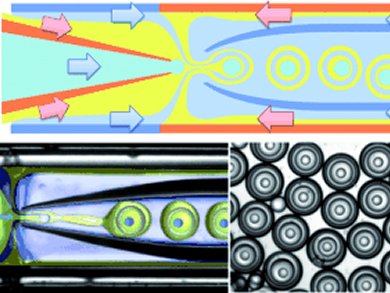

Shin-Hyun Kim and David Weitz, Harvard University, USA, have exploited an ingenious way to make monodisperse multiple emulsion drops of high order using stable biphasic flows in confining channels (see figure). They used a convenient one-step emulsification approach method to form triple and quadruple emulsion drops in step. The droplets are formed in different modes of having water or oil inside or outside.

As quoted by one referee “The work combines great insight into fluids and interfacial energies with potential applications for capsules and inks”.

- One-Step Emulsification of Multiple Concentric Shells with Capillary Microfluidic Devices

S.-H. Kim, D. A. Weitz,

Angew. Chem. Int. Ed. 2011.

DOI: 10.1002/anie.201102946 - S.-H. Kim, D. A. Weitz,

Angew. Chem. 2011.

DOI: 10.1002/ange.201102946