Mechanically agitated reactors involving gas, liquid and solid phases are widely used in biotechnology research and industry. But in spite of its common use, the design and operation of agitated reactors remains a challenging problem because of the complexity given by the three-dimensional circulating and turbulent multiphase flow in the reactor.

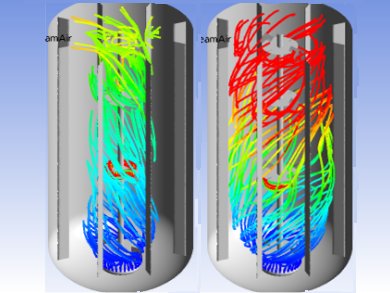

A team around Alfredo Iranzo, University of Seville, with the collaboration of ANALYSIS-DSC, Antibióticos S.A. and Instituto de Biotecnología de León, all Spain, analyzed both the hydrodynamics of the turbulent multiphase flow in an agitated mixing vessel used for a fermentation process and the gas-liquid mixing performance for a range of different impeller design parameters by using Computational Fluid Dynamics (CFD) simulation.

According to their results, the best design configuration to achieve appropriate gas-liquid mixing is defined by a Rushton turbine in the lowest position and three upper pitched-blade turbines with up-pumping flow. This is also the design configuration requiring less power consumption, and therefore it is the most favorable design from the process economics point of view.

- Numerical Investigation of the Effect of Impeller Design Parameters on the Performance of a Multiphase Baffle-Stirred Reactor

A. Iranzo, R. Barbero, J. Domingo, D. Cuadra, J. Costa, J. F. Martín, R. Vicente, J. L. Barredo

Chem Eng. Technol. 2011, 34 (8).

DOI: 10.1002/ceat.201000286