The performance and competitiveness of organic solar cells have improved significantly due to the development of non-fullerene acceptors (NFAs). However, the transfer of laboratory results to industrial manufacturing still needs work. Generally, active layers are deposited using halogenated solvents and various additives using spin coating, followed by thermal annealing.

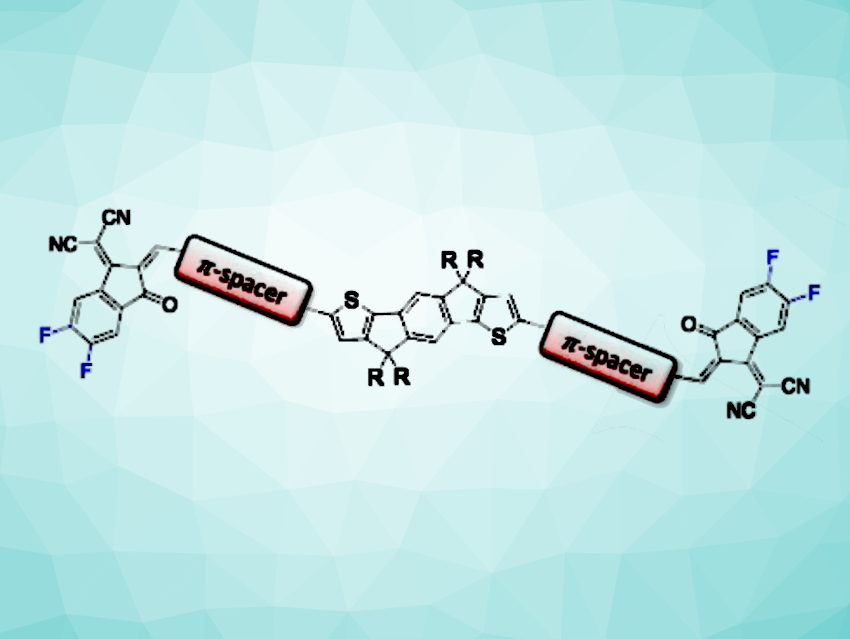

Jörg Ackermann, Aix-Marseille Université, Renaud Demadrille, University Grenoble Alpes, both France, and colleagues have developed four new NFAs that show better absorption in the visible range compared to the well-known acceptor molecule ITIC (pictured below on the right). The new NFAs have an A-π-D-π-A-type structure (pictured above, A = acceptor, π = π-spacer, D = donor), with a central unit based on 4,9-dihydro-s-indaceno[1,2-b:5,6-b’]dithiophene (IDT) flanked by two 4H-indeno[1,2-b]thiophene spacer units and two acceptors at the ends—either 2-(3-oxo-2,3-dihydro-1H-inden-1-ylidene)malononitrile or its fluorinated analog, 2-(5,6-difluoro-3-oxo-2,3-dihydro-1H-inden-1-ylidene)-malonitrile.

Ternary blends of the NFAs with the donor polymer PM6 and ITIC-4F, a fluorinated derivative of ITIC, led to solar cells with efficiencies over 11 %. These ternary blends were processed using non-halogenated solvents, without additives or any thermal post-treatment. Such molecules could help to fulfill industrial requirements and facilitate the manufacturing of organic solar cells.

Ternary blends of the NFAs with the donor polymer PM6 and ITIC-4F, a fluorinated derivative of ITIC, led to solar cells with efficiencies over 11 %. These ternary blends were processed using non-halogenated solvents, without additives or any thermal post-treatment. Such molecules could help to fulfill industrial requirements and facilitate the manufacturing of organic solar cells.

- Non‐Fullerene Acceptors with an Extended Pi‐Conjugated Core: Third Components in Ternary Blends for High‐Efficiency, Post Treatment‐Free, Organic Solar Cells,

Yatzil Alejandra Avalos-Quiroz, Olivier Bardagot, Yann Kervella, Cyril Aumaître, Lydia Cabau, Agnès Rivaton, Olivier Margeat, Christine Videlot-Ackermann, Uyxing Vongsaysy, Jörg Ackermann, Renaud Demadrille,

ChemSusChem 2021.

https://doi.org/10.1002/cssc.202101005